Here is the detailed information about the application fields of chemical suppliers:

I. Industrial Fields

(1) Coatings and Building Materials

- Demand Characteristics

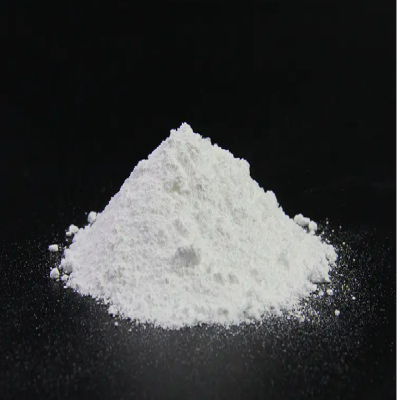

- The production of coatings requires various chemicals such as resins (epoxy resins, acrylic resins, etc.), pigments (titanium dioxide, etc.), solvents (alcohols, ketones, etc.), and additives (flow agents, defoamers, etc.). The performance of these chemicals directly affects key properties of the coatings, such as adhesion, weather resistance, and gloss.

- In the building materials industry, for example, in the production of glass fiber reinforced plastics (GFRP), high-performance resins and curing agents are needed to ensure the strength and durability of the materials.

- Supplier Role

- chemical suppliers need to provide a stable supply of chemicals and ensure the consistency of product quality. For example, for epoxy resins, chemical suppliers must ensure that their epoxy value, viscosity, and other indicators meet the requirements of the coating formula.

- At the same time, chemical suppliers need to develop and provide new types of chemicals based on the development trends of the coatings and building materials industries. For instance, with the increasing demand for environmentally friendly coatings, chemical suppliers need to adjust their product structures in a timely manner and provide waterborne resins that meet environmental standards.

(2) Papermaking and Membrane Technology

- Demand Characteristics

- The papermaking process requires a large number of chemicals, including papermaking chemicals (sizing agents, retention aids, etc.), bleaching agents (hydrogen peroxide, etc.), and wastewater treatment chemicals (flocculants, etc.). These chemicals are used to improve paper quality, optimize the papermaking process, and treat wastewater.

- In the field of membrane technology, the chemicals used to manufacture various membrane materials (such as reverse osmosis membranes, nanofiltration membranes, etc.) have extremely high requirements. For example, to produce high-performance reverse osmosis membranes, special polymer monomers and crosslinking agents are needed to ensure the porosity, selectivity, and mechanical strength of the membranes.

- Supplier Role

- chemical suppliers need to provide high-purity, low-impurity chemicals to ensure the stability of the papermaking and membrane manufacturing processes and the quality of the products. For example, for papermaking sizing agents, chemical suppliers must ensure the content and stability of the active ingredients to meet the sizing requirements of the paper.

- In the field of membrane technology, chemical suppliers need to work closely with membrane manufacturers and customize chemicals based on the performance requirements of the membranes (such as separation accuracy, chemical resistance, etc.). For example, for seawater desalination reverse osmosis membranes, chemical suppliers need to provide polymer raw materials and crosslinking agents that can withstand high salinity and high-pressure environments.

(3) Lubricants

- Demand Characteristics

- The production of lubricants requires base oils and various additives. Base oils need to have good viscosity-temperature performance, oxidation stability, and lubricity. Additives include antioxidants, anti-wear agents, detergents, and dispersants, which are used to improve the performance of lubricants.

- Different application scenarios have different performance requirements for lubricants. For example, automotive engine lubricants need to maintain good lubrication and cleaning performance under high-temperature and high-load conditions, while industrial gear oils need to have higher load-carrying capacity and anti-wear performance.

- Supplier Role

- chemical suppliers need to provide high-quality base oils and additives. For base oils, chemical suppliers must ensure that their viscosity index, flash point, and other indicators meet the requirements of the lubricant formula. For additives, chemical suppliers need to ensure the content and dispersibility of the active ingredients to fully utilize the function of the additives.

- At the same time, chemical suppliers need to develop new types of additives based on the development trends of the lubricant industry. For example, with the increasing demand for environmentally friendly lubricants, chemical suppliers need to adjust their product formulas in a timely manner and provide low-sulfur, low-phosphorus additives that meet environmental requirements.

(4) Oil Fields and Water Treatment

- Demand Characteristics

- The oil field exploitation process requires a large number of chemicals, such as drilling fluid additives (viscosity enhancers, filtration loss reducers, etc.), demulsifiers, and scale inhibitors. These chemicals are used to optimize drilling processes, improve oil extraction efficiency, and prevent equipment scaling.

- In the water treatment field, flocculants, biocides, and scale inhibitors are needed. For example, in industrial circulating water systems, scale inhibitors are used to prevent the formation of scale, and biocides are used to inhibit the growth of microorganisms.

- Supplier Role

- chemical suppliers need to provide chemicals that are suitable for oil field and water treatment processes. For oil field chemicals, chemical suppliers need to provide customized chemicals based on different geological conditions and exploitation processes. For example, for high-salinity oil reservoirs, chemical suppliers need to provide drilling fluid additives that are resistant to high salinity.

- In the water treatment field, chemical suppliers need to provide efficient and environmentally friendly chemicals. For example, developing new biodegradable flocculants to reduce environmental impact.

II. Pharmaceuticals and Food

(1) Pharmaceuticals

- Demand Characteristics

- The pharmaceutical R&D and production process has extremely high requirements for the purity and quality of chemicals. For example, in the process of drug synthesis, the purity of raw materials and intermediates directly affects the quality and efficacy of the drugs.

- The pharmaceutical industry also requires a large number of reagents and solvents, such as high-purity ethanol and acetone, which are used in drug extraction and purification processes.

- At the same time, the pharmaceutical industry has strict compliance requirements for chemicals, and chemical suppliers need to provide chemicals that meet Good Manufacturing Practice (GMP) standards.

- Supplier Role

- chemical suppliers need to provide high-purity, high-stability chemicals and ensure that their products meet the quality standards of the pharmaceutical industry. For example, for raw materials, chemical suppliers need to provide detailed quality inspection reports, including purity, impurity content, and other indicators.

- chemical suppliers also need to work closely with pharmaceutical companies and provide customized chemicals based on the needs of drug R&D and production. For example, for the synthesis of some new drugs, chemical suppliers may need to develop and provide special intermediates.

(2) Food Industry

- Demand Characteristics

- The food industry requires food-grade additives and raw materials, and these chemicals must meet food safety standards. For example, the use of food preservatives (such as sodium benzoate), sweeteners (such as sucralose), and colorants is strictly regulated by laws and regulations.

- The food processing process also requires a large number of food-grade auxiliaries, such as emulsifiers and stabilizers, which are used to improve the texture and taste of food.

- The food industry also has high requirements for the stability of chemicals. For example, additives used in high-temperature baking processes need to have good thermal stability.

- Supplier Role

- chemical suppliers need to provide chemicals that meet food safety standards and provide relevant certification documents, such as food additive production licenses. For example, for food colorants, chemical suppliers need to ensure that they meet national food safety standards and provide relevant test reports.

- chemical suppliers also need to develop and provide new types of food additives based on the development trends of the food industry. For example, with the increasing demand for healthy foods from consumers, chemical suppliers can develop natural, low-sugar, and low-salt food additives.

III. Electronics and Personal Care

(1) Electronics

- Demand Characteristics

- The electronics industry has extremely high requirements for the purity and stability of chemicals. For example, in the semiconductor manufacturing process, the purity of chemicals such as photoresists and etching liquids directly affects the quality and performance of chips.

- The electronics industry also requires a large number of electronic chemicals, such as electronic-grade hydrofluoric acid and electronic-grade sulfuric acid, which are used in cleaning and etching processes.

- At the same time, the electronics industry has strict requirements for particle control in chemicals, as the presence of particles can lead to defects in chip manufacturing processes.

- Supplier Role

- chemical suppliers need to provide ultra-high-purity chemicals and ensure the stability of their products. For example, for electronic-grade hydrofluoric acid, chemical suppliers need to ensure that its purity reaches above 99.999% and control the content of metal ion impurities.

- chemical suppliers also need to develop and provide new types of electronic chemicals based on the development trends of the electronics industry. For example, with the continuous upgrading of chip manufacturing processes, chemical suppliers need to provide higher-purity, lower-impurity chemicals to meet the needs of advanced processes.

(2) Personal Care Industry

- Demand Characteristics

- The personal care products (such as cosmetics, skincare products, etc.) need to use chemicals that meet safety standards. For example, the safety of components such as fragrances, preservatives, and surfactants used in cosmetics needs to be strictly assessed.

- The personal care industry also has high requirements for the sensory properties of chemicals. For example, the texture and fragrance of skincare products can affect consumers' usage experience.

- At the same time, with the increasing preference of consumers for natural and environmentally friendly products, the demand for naturally sourced chemicals in the personal care industry is also increasing.

- Supplier Role

- chemical suppliers need to provide chemicals that meet safety standards