The global Heat Resistant Polymer Market is witnessing a strong upward trajectory, fueled by increasing demand for materials capable of withstanding extreme temperatures and harsh environments across various industries. With the rise of advanced manufacturing techniques and expanding industrial sectors, heat resistant polymers are becoming indispensable for applications requiring superior thermal stability and mechanical strength.

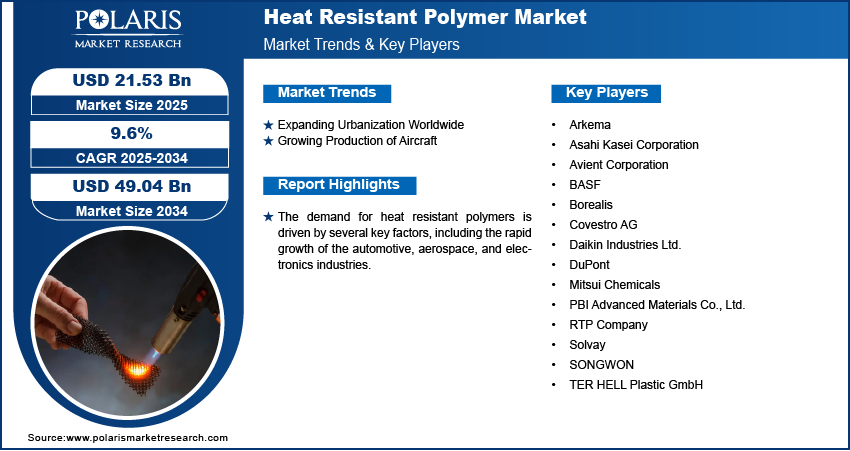

The global heat resistant polymer market size was valued at USD 19.68 billion in 2024, growing at a CAGR of 9.6 % during 2025–2034.

Market Overview

Heat resistant polymers, often classified as high-performance polymers, are engineered to maintain structural integrity and performance at elevated temperatures. These materials play a crucial role in sectors such as automotive, aerospace, electronics, electrical & electronics, chemical processing, and oil & gas, where exposure to high temperatures and corrosive environments is common.

Their exceptional ability to resist degradation, maintain dimensional stability, and deliver reliable performance under thermal stress makes heat resistant polymers a preferred choice over traditional materials like metals or standard plastics. Innovations in polymer chemistry and processing techniques are driving continuous enhancements in polymer properties, expanding their applicability in sophisticated industrial applications.

Key Market Trends

- Growing Demand for Thermal Stability in Electronics and Automotive

As electronic devices become more compact and automotive engines operate at higher temperatures for improved efficiency, the requirement for polymers with outstanding thermal stability has surged. Heat resistant polymers are used extensively in insulation, connectors, and under-the-hood automotive components to ensure durability and safety. - Material Innovation Driving Next-Generation Polymers

Continuous research and development efforts are leading to new grades of heat resistant polymers with enhanced flame retardancy, chemical resistance, and mechanical toughness. These material innovations enable manufacturers to tailor polymers to specific high-temperature environments. - Sustainability and Recycling Initiatives

Increasing environmental concerns are pushing the development of recyclable and bio-based heat resistant polymers. Manufacturers are focusing on sustainable polymer solutions without compromising on heat resistance and performance. - Expansion of Industrial Manufacturing in Emerging Economies

Rapid industrialization in Asia-Pacific, Latin America, and the Middle East is boosting the demand for high-performance polymers. These regions are witnessing increased adoption of heat resistant polymers to support their growing automotive, electronics, and chemical processing industries.

Country-Wise Market Analysis

United States

The United States stands as a significant market for heat resistant polymers, driven by its robust aerospace, automotive, and electronics sectors. The country’s emphasis on advanced manufacturing and lightweight material adoption is fueling demand for polymers with superior thermal stability.

Government initiatives promoting energy efficiency and emission reductions are accelerating the use of high-performance polymers in engine components and electronic devices. The U.S. market also benefits from strong R&D infrastructure enabling continuous material innovation in heat resistant polymer formulations.

Germany

Germany’s market is characterized by its precision engineering and automotive industry leadership. The demand for heat resistant polymers in Germany is closely linked to automotive and industrial machinery applications requiring materials that withstand extreme operating conditions.

With strict regulations on environmental safety and emissions, German manufacturers prioritize polymers that provide both thermal stability and sustainability. This has led to increased use of flame-retardant and chemically resistant heat resistant polymers in manufacturing.

China

China represents one of the fastest-growing markets for heat resistant polymers, propelled by rapid industrialization and expansion of the electronics and automotive sectors. The country’s push toward electric vehicles and renewable energy technologies is driving demand for polymers that perform reliably under high temperatures.

China’s growing chemical and polymer production capabilities are enhancing local availability of high-quality heat resistant polymers. The focus on industrial applications involving thermal management and electrical insulation continues to widen the market potential.

Read More @ https://www.polarismarketresearch.com/industry-analysis/heat-resistant-polymer-market

Japan

Japan’s stronghold in electronics and precision machinery manufacturing underpins its significant demand for heat resistant polymers. The market benefits from Japan’s advanced research in high-performance polymers, resulting in materials that meet stringent heat and chemical resistance requirements.

Japanese manufacturers emphasize integrating heat resistant polymers in electronic components, automotive parts, and medical devices. The country’s market trends also include the development of recyclable polymers aligned with global sustainability goals.

South Korea

South Korea’s electronics and automotive industries are the primary drivers for heat resistant polymer demand. The country is renowned for its advanced semiconductor and consumer electronics manufacturing, where polymers with excellent thermal stability and electrical insulation properties are critical.

Material innovation is a key focus, with South Korean companies investing in new heat resistant polymer grades that support miniaturization and high reliability in harsh thermal environments.

India

India’s expanding industrial base and increasing adoption of modern manufacturing technologies are propelling the heat resistant polymer market growth. The automotive and electrical sectors are the primary end-users, with polymers increasingly replacing metals and conventional plastics in components exposed to elevated temperatures.

Ongoing infrastructure development and government policies encouraging Make in India initiatives are expected to boost local production and consumption of heat resistant polymers tailored for regional industrial applications.

France

France’s heat resistant polymer market is growing steadily, supported by aerospace, automotive, and chemical processing industries. The country’s commitment to innovation and green technologies is pushing demand for polymers that combine thermal stability with environmental friendliness.

French manufacturers prioritize polymers that can endure extreme temperatures and corrosive environments, particularly for aerospace and energy sector applications.

Brazil

Brazil is an emerging market with growing demand for heat resistant polymers in automotive, electronics, and energy sectors. Increasing industrial activities and infrastructure projects are driving polymer adoption for applications requiring high temperature resistance and durability.

Brazilian manufacturers and importers are focusing on polymers that offer cost-effective solutions while meeting international quality and safety standards for thermal applications.

Conclusion

The global Heat Resistant Polymer Market is set for substantial growth driven by the expanding need for materials that can perform reliably under high temperature and harsh conditions. The shift towards high-performance polymers in industries such as automotive, electronics, aerospace, and chemical processing is reshaping material choices worldwide.

Country-specific insights reveal diverse growth drivers: the U.S. and Germany focus on advanced manufacturing and sustainability; China and India leverage rapid industrialization; Japan and South Korea lead in electronics and precision polymers; while emerging markets like Brazil and France are expanding demand in specialized sectors.

More Trending Latest Reports By Polaris Market Research:

Activated Bleaching Earth Market

Active Calcium Silicate Market