Understanding the Pros and Cons of Fixed and Mobile Crushing Solutions

In the field of material processing and aggregate production, choosing between a stationary crushing system and a mobile crusher setup is a critical decision that directly affects operational efficiency, investment costs, and site flexibility. A China Stationary Crusher refers to a fixed crushing unit installed at a designated location, typically in large-scale mining or industrial crushing plants. These systems are engineered for high-volume, long-term production at sites where mobility is not a primary concern. On the other hand, mobile crushers are designed with flexibility and mobility in mind, allowing them to be transported between job sites or relocated within a project area as needed. Each type of crusher setup offers distinct advantages and comes with its own set of trade-offs depending on the specific application, site conditions, and production demands.

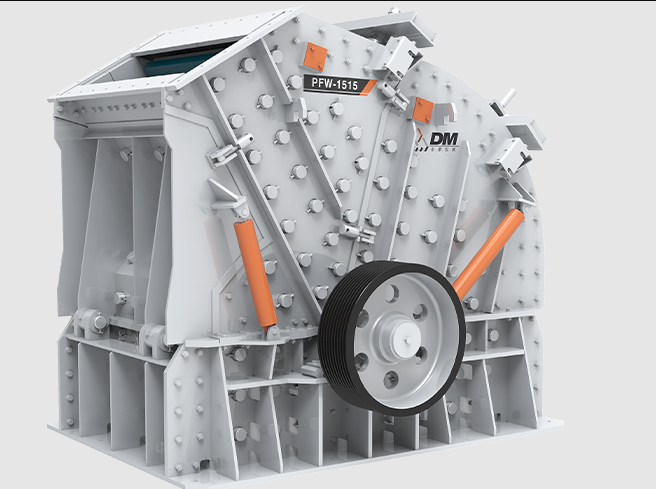

Stationary crushing equipment excels in applications where large-scale, continuous operation is required. These systems typically offer higher capacity, greater crushing power, and more robust structures that can handle heavy-duty materials like hard rock, iron ore, and construction debris. Because they are fixed in place, these units can be integrated into complex crushing and screening lines with conveyors, feeders, and secondary crushers to create a complete processing system. Maintenance is often easier to manage with stationary units, as their size and setup allow for better access to critical components. Additionally, they are generally more energy-efficient over long periods of operation, especially when processing large quantities of material.

Despite their power and efficiency, fixed crushing plants have notable limitations in terms of flexibility and initial installation cost. The setup process for a China Stationary Crusher can be time-consuming and capital-intensive, requiring site preparation, foundation construction, and utility connection. This makes them unsuitable for temporary projects, remote locations, or applications where the production site may change over time. If a company needs to shift operations to a new site, the entire stationary system must be dismantled, relocated, and reinstalled, which leads to considerable downtime and labor costs. Therefore, these systems are best suited for long-term, high-yield operations where production stability is more valuable than mobility.

In contrast, mobile crushers offer unmatched flexibility, particularly in the construction, demolition, and recycling industries. These self-contained units can be easily transported between locations using trucks or trailers and can begin operations shortly after arrival without major setup. This agility is especially beneficial for short-term projects or operations spread across multiple locations. Mobile crushers also allow producers to respond quickly to changing production needs, weather conditions, or material availability. They are often equipped with advanced control systems and user-friendly interfaces that make operation straightforward even in rugged outdoor environments.

However, mobile crushers tend to have lower capacity compared to fixed units and may not handle extremely hard materials as effectively. Their compact design, while beneficial for transport and setup, may limit the size of components and the available power for certain applications. Additionally, operating costs over the long term can be higher due to fuel consumption, frequent relocation, and wear caused by transport vibrations. For operators requiring continuous large-scale output, mobile solutions may not provide the same level of productivity as a stationary system.

Ultimately, the decision between using a China Stationary Crusher or a mobile crusher depends on various factors such as project duration, material type, production targets, site accessibility, and budget. Each option offers unique strengths that can be maximized when aligned with the specific goals and limitations of a given operation. For permanent, high-volume sites, a stationary crusher may offer unmatched efficiency and reliability. Conversely, for dynamic, mobile environments or short-cycle projects, mobile crushers provide the adaptability and responsiveness needed to stay competitive.

Machinery Weight19.8-40.2t

Max Feeding size(mm)≤350mm

Hopper Volume(m³)160-600t/h