Car bumper molding is an essential component in the automotive industry, providing both functional and aesthetic benefits to vehicle designs. The molding process involves shaping materials like plastic, rubber, or metal into specific forms that fit around the bumper area of a vehicle. Bumper moldings not only enhance the overall look of a car but also offer protection to the vehicle, helping absorb impacts and preventing damage to the body.

Bumper moldings serve a variety of purposes. One of the primary roles is to protect the bumper from scratches, dents, and other minor damages caused by everyday driving. These moldings can help absorb light impacts, reducing the risk of damage to the more expensive parts of the car, such as the frame or fenders. In addition, bumper moldings often feature built-in sensors or reflectors, which can improve safety by enhancing visibility, particularly during nighttime driving.

The materials used for car bumper molding vary, but they are typically durable and capable of withstanding impact. Thermoplastic materials like polypropylene and ABS (Acrylonitrile Butadiene Styrene) are commonly used for their lightweight properties and resistance to heat and chemicals. Rubber or polyurethane may also be used for their flexibility and shock-absorbing qualities. The choice of material depends on the type of vehicle and the specific requirements of the bumper, such as flexibility, weight, and cost.

Apart from protection, bumper moldings also contribute to the vehicle's appearance. Manufacturers use molding techniques to create sleek, attractive designs that complement the car's overall look. These moldings come in various styles and finishes, including matte, glossy, or textured surfaces, allowing for customization according to consumer preferences.

https://www.bumpermould.net/product/bumper-mould/plastic-injection-front-rear-bumper-mould-for-2021-benz-gls.html

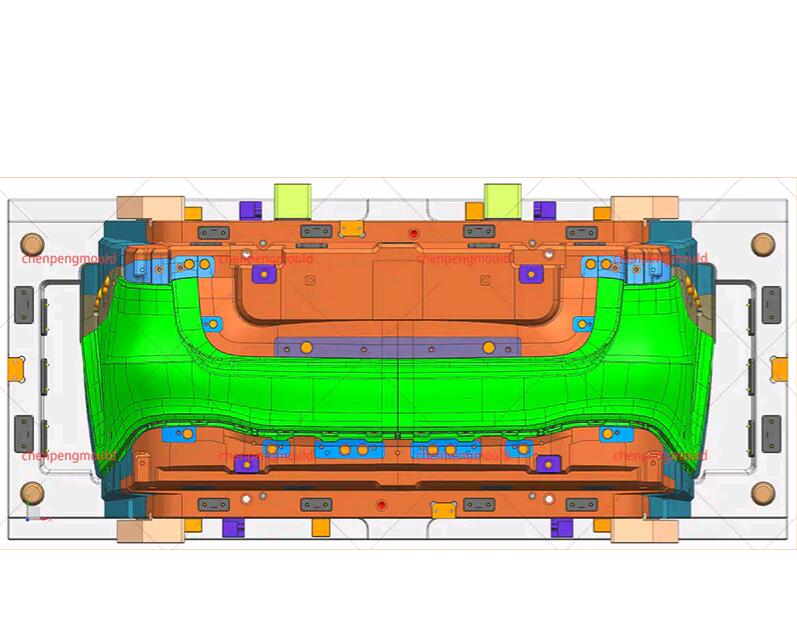

Mould Name Benz GLS Bumper Mould

Material PP EPDM

Bumper Size 2100*610*560mm

Steel For Cavity &. Core P20

Mould Base C45

NOs. of Cavity 1*1

Injection System Yudo 5 direct injection gates

Ejection System Ejector pins, angle lifters

Mould Standard OEM/HASCO

Mould Estimated Size 2550 x 1200 x 1050mm