Bumper injection molding is a widely adopted process in the automotive industry due to its ability to produce large, durable, and complex components with consistency. This method relies on injecting molten thermoplastic materials, such as polypropylene or polycarbonate blends, into a specially designed mold. The resulting parts meet both functional and aesthetic requirements, making the technique particularly suitable for car bumpers.

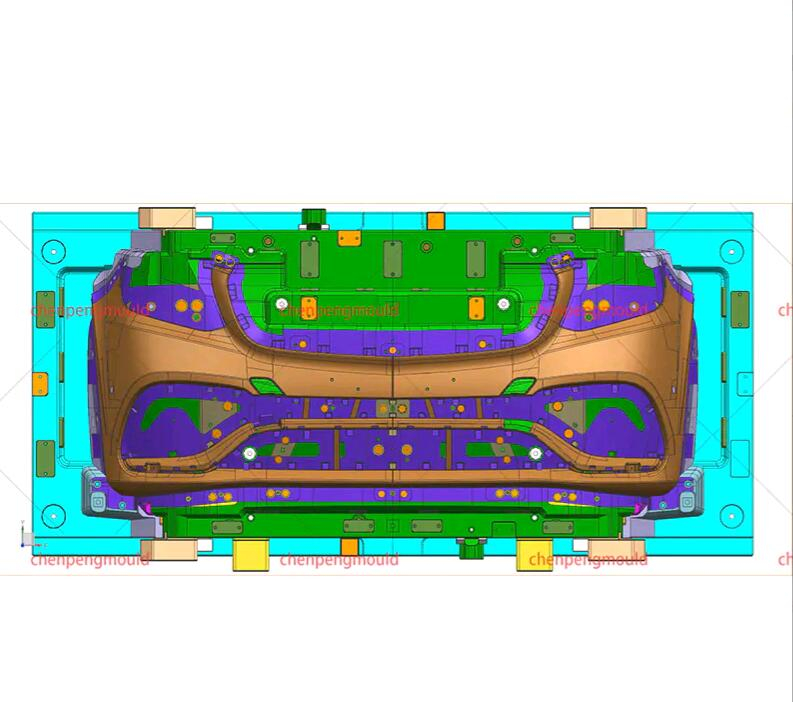

One of the defining characteristics of bumper injection molding is its capacity for high precision. Automotive bumpers must align with strict safety and design standards, and the process ensures uniform thickness, smooth surfaces, and reliable fit. In addition, it allows the integration of design details such as mounting points and reinforcing ribs directly into the mold, reducing the need for secondary operations.

Another notable feature is efficiency. Injection molding supports large-scale production with relatively low cycle times, making it cost-effective for manufacturers. At the same time, the process supports a wide range of material options, allowing flexibility in balancing impact resistance, weight, and surface finish.

Finally, bumper injection molding contributes to sustainability efforts. Many thermoplastics used in bumpers are recyclable, and modern processes are increasingly focused on reducing waste and optimizing energy use. This makes the method compatible with the automotive industry’s long-term goals of resource efficiency and environmental responsibility.

Bumper injection molding stands out for its precision, production efficiency, and adaptability, making it a vital technique in modern vehicle manufacturing.

https://www.bumpermould.net/product/bumper-mould/no-flash-mercedesbenz-gls-maybach-front-bumper-mould.html

Why choose us?

Experience: We have had strong expertise in designing and developing automotive injection molds since 2000. Our company has developed 1000 bumper molds, including Volkswagen, Audi, Mercedes, BMW, Toyota, Ford, Skoda, etc. Moreover, we also developed higcarsbumper bumpers, like Rolls-Royce, Lamborghini I, Porsche Panam, er, an, etc.

Performance: Our bumper molds consistently deliver higher precision and quality in the molded parts compared to others.

Uniqueness:O ur bumper molds have unique features and innovations that set them apart. It includes advanced cooling systems, innovative design elements, and special coatings that improve durability and reduce cycle times.

Quality AssAssurancestressesss our commitment to quality assurance processes and standards that ensure the reliability and consistency of our bumper mold's output.