According to the latest market analysis, the global ceramic balls market , valued at USD 442.9 million in 2018 , is projected to reach USD 892.2 million by 2027 , expanding at a compound annual growth rate (CAGR) of 8.1% over the forecast period 2019–2027. The growth is driven by rising demand across key industries such as aerospace, automotive, chemical processing , and oil & gas , where ceramic balls are proving essential due to their superior mechanical and thermal properties.

The new market report, titled “Ceramic Balls Market to 2027 – Global Analysis and Forecasts by Material (Zirconia, Silicon, Alumina, and Others); Function (Active and Inert); Application (Aerospace, Automotive, Chemical, and Others); and Geography” , provides an in-depth analysis of trends, market dynamics, and strategic developments influencing the ceramic balls industry worldwide.

Unmatched Performance Driving Industry Adoption

Ceramic balls, known for their exceptional resistance to wear, corrosion, high temperatures, and mechanical stress , have become critical components in several high-precision applications. Unlike traditional steel or plastic balls, ceramic variants deliver longer service life and better performance in harsh environments.

“These materials are redefining performance standards across multiple industries,” said a senior analyst from [Your Company Name]. “Whether it's reducing friction in high-speed bearings or supporting catalysts in chemical reactors, ceramic balls are setting the benchmark for reliability and efficiency.”

Key Market Segmentation and Insights

By Material:

The report segments the ceramic balls market based on material into:

-

Zirconia : Dominates the market due to its outstanding toughness, high density, and thermal resistance. Extensively used in medical, dental, and high-load mechanical applications.

-

Silicon-based Ceramics (eg, Silicon Nitride) : Gaining traction in aerospace and automotive sectors for their lightweight and durable properties.

-

Alumina : Widely used in chemical processing and electrical insulation due to its affordability and excellent chemical stability.

-

Others : Includes emerging ceramic materials such as steatite and advanced composites, serving specialized industrial needs.

By Function:

Ceramic balls are categorized by function into:

-

Active Ceramic Balls : These are dynamic components used in bearings, valves, flow meters, and grinding media . Their high load-bearing capacity and low friction make them ideal for mechanical systems.

-

Inert Ceramic Balls : Often used as support media in chemical processing and filtration , particularly in refineries, gas treatment plants, and catalytic processes .

By Application:

-

Aerospace : Increasing usage in fuel systems, actuators, and high-speed bearing assemblies , where weight reduction and reliability are crucial.

-

Automotive : Used in engine components, transmissions, and electric vehicles (EVs) for enhanced fuel efficiency and reduced maintenance.

-

Chemical Industry : Plays a vital role in catalyst bed support, filtration, and separation processes .

-

Others : Includes medical devices, electronics, water treatment , and renewable energy applications.

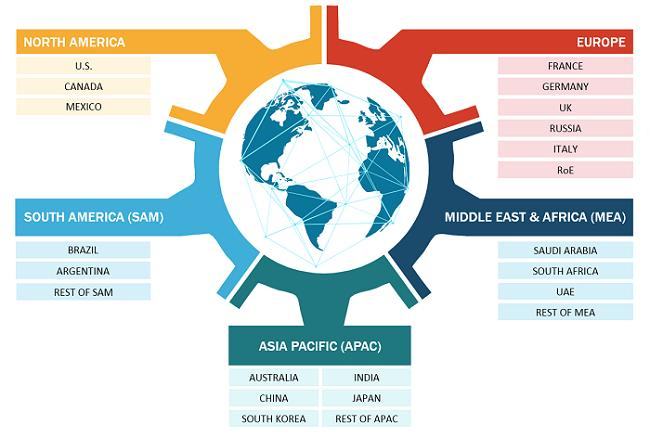

Geographic Expansion and Growth Opportunities

The report provides comprehensive regional analysis, highlighting key growth areas:

-

North America : A mature market with strong demand from aerospace and industrial automation sectors. The US continues to lead in innovation and high-value applications.

-

Europe : Driven by strict environmental and efficiency regulations, particularly in Germany, France, and the UK .

-

Asia-Pacific : Expected to register the highest CAGR during the forecast period. Rapid industrialization in China, India, Japan, and South Korea is propelling demand for ceramic components in manufacturing and energy.

-

Middle East & Africa : High demand for inert ceramic balls in oil & gas and petrochemical sectors , particularly in Saudi Arabia and UAE .

-

South America : Steady growth due to increasing investment in infrastructure and chemical processing industries .

Key Drivers of Market Growth

-

Rising Demand in High-Performance Applications

Industries are increasingly turning to ceramics to meet performance requirements that metals or plastics cannot. Ceramic balls provide higher reliability and longer operational life, reducing total cost of ownership. -

Automotive and EV Revolution

The global shift toward electric vehicles is creating new avenues for ceramic balls in lightweight drivetrains, battery systems, and regenerative braking components. -

Growth in Chemical Processing and Oil & Gas

With growing investments in refineries and petrochemical plants , inert ceramic balls are becoming vital for catalyst bed support and gas filtration systems . -

Technological Advancements and Material Innovation

The development of hybrid ceramic materials and improvements in manufacturing techniques such as additive manufacturing (3D printing) are expanding product capabilities and reducing production costs.

Challenges and Restraints

While the ceramic balls market presents promising growth opportunities, it also faces challenges:

-

High Initial Costs : The production of advanced ceramics remains cost-intensive due to complex sintering and machining processes.

-

Limited Awareness in Emerging Markets : Despite their advantages, ceramic balls are underutilized in some developing economies due to lack of education and cost sensitivity.

-

Recycling and Disposal Issues : Unlike metals, ceramics are less recyclable, prompting the need for sustainability-focused innovations in material engineering.

However, ongoing R&D efforts and rising awareness are expected to address these constraints, creating a more favorable environment for market expansion.

Competitive Landscape

The ceramic balls market is moderately fragmented with the presence of global and regional players. Key market participants are focusing on:

-

New Product Development

-

Strategic Collaborations

-

Geographic Expansion

-

Investment in R&D

Major players include:

-

Industrial Tectonics Inc.

-

Toshiba Materials Co., Ltd.

-

CoorsTek Inc.

-

Axens

-

Trinity Ceramic Supply

-

Topack Ceramics Pvt. Ltd.