In the electrical manufacturing industry, the significance of a reliable EI Transformer Factory is evident in the way it influences quality, stability, and overall performance of electrical systems. Transformers built with EI cores are widely used in power supplies, lighting applications, control systems, and other electronic equipment where dependable voltage regulation is necessary. Factories specializing in such components focus not only on production but also on innovation, testing, and compliance with industry standards.

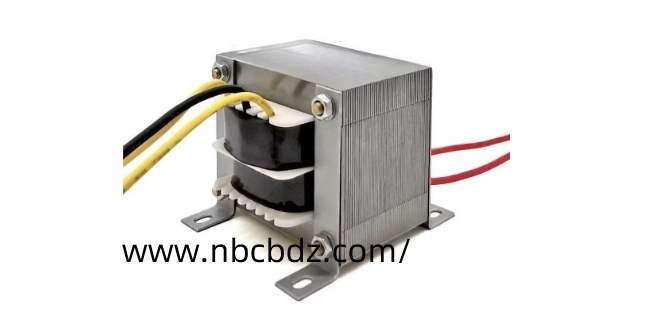

The EI core design, shaped like the letters "E" and "I", provides structural stability while minimizing magnetic losses. This structure is known for balancing efficiency with durability, making it suitable for both small appliances and industrial equipment. By ensuring precise winding techniques and material selection, manufacturers can produce transformers that deliver reliable performance in diverse applications.

One of the core strengths of specialized facilities lies in their ability to adapt to customer requirements. Many businesses need custom solutions—whether it is a particular voltage rating, insulation class, or thermal resistance. A well-established production line allows factories to offer flexibility, ensuring transformers meet specific operational environments.

Safety is another priority in transformer production. Factories invest in rigorous quality control, from raw material selection to final inspection. Electrical insulation, heat resistance, and winding precision are tested to prevent malfunction and guarantee user safety. These practices align with global regulations, making such products suitable for international markets.

Sustainability is also becoming a key focus. Many production facilities are integrating eco-friendly materials, reducing energy consumption in the production process, and designing transformers with higher efficiency to cut energy losses during operation. This aligns with the increasing demand for energy-conscious technologies.

Furthermore, automation and advanced machinery play a role in improving accuracy and productivity. By implementing automated winding, testing, and assembly systems, factories enhance consistency while reducing production time. This not only ensures better scalability but also allows companies to remain competitive in a global marketplace.

Ultimately, a dedicated transformer factory provides more than just components—it offers solutions. From product customization to compliance with safety and efficiency standards, such facilities support industries in building reliable systems that power everyday life. As electrical demands continue to grow, the role of specialized production sites becomes even more vital in meeting future challenges.

For further details, please visit https://www.nbcbdz.com/product/