In the field of power distribution and electronics, a dedicated Low-frequency Transformer Factory plays an essential role in producing transformers that ensure stable voltage, improved efficiency, and safety for industrial and consumer applications. Factories specializing in low-frequency transformers focus on precision engineering, quality materials, and advanced production processes to deliver reliable performance.

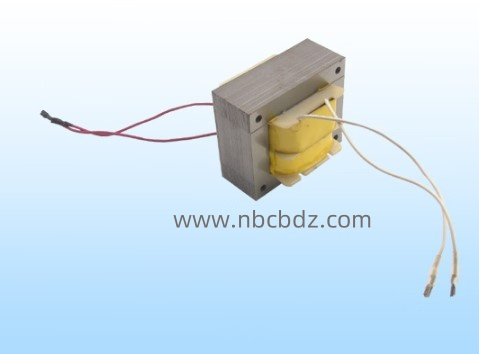

Low-frequency transformers are widely used in power grids, audio equipment, and industrial machinery where steady voltage and current management are critical. The factory combines traditional craftsmanship with modern automation to produce transformers that meet exacting standards. Every stage, from winding coils to insulating materials, is carefully controlled to maintain performance, safety, and durability.

One of the core advantages of a professional factory is its commitment to quality assurance. Through automated inspection, rigorous testing, and detailed monitoring of materials, the factory ensures that every transformer meets technical specifications. High attention to detail prevents defects, reduces maintenance issues, and provides consistent electrical output. These practices are particularly important for low-frequency transformers that operate under heavy loads for extended periods.

Modern low-frequency transformer manufacturing also emphasizes energy efficiency and sustainability. Factories optimize material use, reduce waste, and implement energy-saving technologies during production. By combining eco-friendly practices with high-precision engineering, manufacturers provide solutions that are not only efficient but also aligned with global environmental standards.

Flexibility in production is another key feature. Customers may require transformers for different voltages, power capacities, and applications. A capable factory can adapt its production lines to accommodate these variations without compromising quality or reliability. This adaptability allows clients to receive customized solutions tailored to their specific operational needs.

Safety remains a fundamental consideration in transformer production. Low-frequency transformers often carry significant electrical loads, so careful insulation, thermal management, and protective measures are incorporated into each design. Factory engineers ensure compliance with safety standards and testing protocols, giving clients confidence in the long-term performance and reliability of their equipment.

In addition to manufacturing excellence, strong technical support and customer service are vital. Factories often provide guidance on installation, maintenance, and troubleshooting, helping clients maximize the lifespan and efficiency of their transformers. Knowledgeable support teams contribute to stronger relationships and higher satisfaction among industrial and commercial customers.

Investing in high-quality low-frequency transformer production ensures that power systems operate efficiently, safely, and reliably. By combining skilled engineering, sustainable practices, and attentive client support, a reputable Low-frequency Transformer Factory contributes significantly to modern electrical systems and infrastructure.

For more details, visit https://www.nbcbdz.com/product/