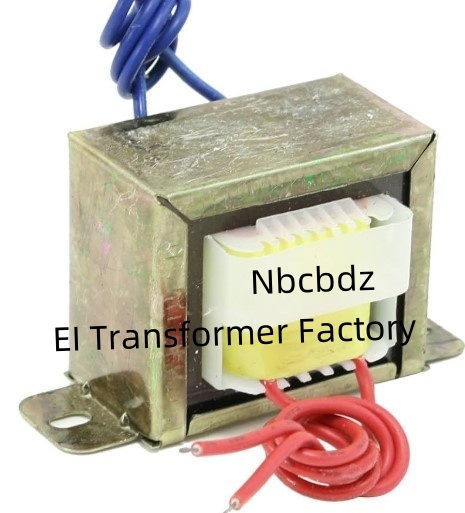

When evaluating production quality in the electrical industry, an EI Transformer Factory represents more than a manufacturing site; it reflects the integration of engineering, material science, and precision assembly that ensures reliable energy conversion across multiple applications. Transformers of this type are central to circuits requiring voltage regulation, stability, and long-term performance, making the factory environment vital to both consistency and innovation.

Inside such facilities, careful planning and workflow management are essential. Each unit moves through a sequence of stages including material preparation, winding, lamination, and testing. By standardizing these steps, production teams are able to achieve uniform results while still adapting to the needs of various markets. For example, devices designed for audio equipment may emphasize low noise characteristics, whereas units for industrial tools prioritize durability and efficiency.

The importance of quality control cannot be overstated. Testing procedures are embedded at each stage to verify insulation strength, winding balance, and energy efficiency. Only by catching potential faults early can downtime, material waste, and customer dissatisfaction be minimized. Factories specializing in EI transformers often implement automated testing alongside skilled technician inspections, combining the strengths of technology and human expertise.

Another essential aspect of production is the choice of raw materials. Cores, typically made from silicon steel, must be cut with precision to reduce energy loss, while winding wire and insulation materials must meet exact standards for both safety and performance. A factory that pays attention to sourcing ensures its products remain competitive in a wide range of industries including consumer electronics, lighting, and renewable energy systems.

Environmental responsibility has also become a growing priority. Many facilities are adjusting their practices to align with global expectations for sustainability, focusing on energy-efficient processes, recycling of scrap materials, and safer working environments. These steps not only benefit the planet but also demonstrate corporate accountability in a marketplace where sustainability increasingly influences purchasing decisions.

Customization is another defining element. Clients often seek transformers designed for specific performance ranges, mechanical dimensions, or mounting styles. Factories capable of delivering tailored solutions offer manufacturers flexibility without sacrificing reliability. This adaptability highlights the importance of combining engineering knowledge with practical manufacturing capacity.

In essence, such a factory is not only a supplier but also a partner for industries seeking consistent electrical performance. Whether supporting telecommunications, automation, or daily household electronics, the steady output of EI transformers contributes quietly but indispensably to modern life.

For those considering collaboration with a trusted manufacturer, detailed insights and product information can be explored further here https://www.nbcbdz.com/product/