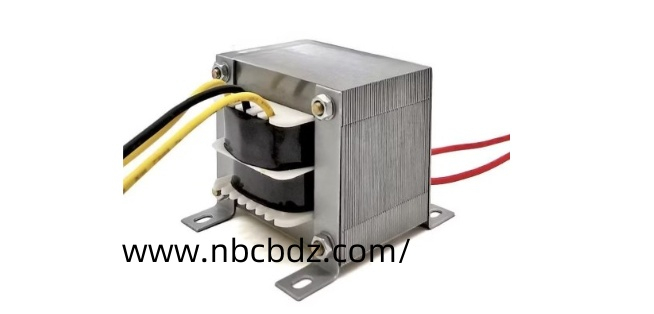

EI Transformer Factory plays an important role in providing reliable electrical solutions that support various industrial and commercial applications. Within the field of modern electronics, transformers are essential components that help regulate voltage, ensure efficiency, and maintain stable performance across multiple systems. As industries continue to demand precision and durability, the focus on consistent production methods and quality control has become even more significant.

One of the key aspects of a transformer manufacturing facility is the ability to combine advanced design practices with skilled craftsmanship. Each unit produced requires careful attention to material selection, winding techniques, and insulation handling. These elements directly influence the functionality of the transformer, making manufacturing standards a vital part of the overall process. Rather than being seen as simple devices, transformers represent a bridge between energy generation and usage, and their construction requires both technical knowledge and practical experience.

Factories engaged in transformer production often emphasize efficiency in their workflow. This includes automated systems for winding, specialized machinery for core assembly, and careful testing procedures before final shipment. The ability to standardize these steps ensures that each product meets the required specifications while minimizing variations. In addition, safety guidelines are strictly followed to ensure that every unit is capable of functioning in demanding environments without compromising performance.

Another important factor is customization. Many industries require specific transformer designs to match their operational conditions. Manufacturers can respond to these needs by offering variations in configuration, such as different shapes, sizes, and insulation methods. By providing flexible options, a factory can better support clients ranging from electronics producers to heavy machinery operators. This adaptability demonstrates how transformers continue to evolve alongside industrial progress.

Sustainability has also become a central topic within transformer manufacturing. Factories are increasingly aware of environmental responsibilities and often explore methods to reduce energy waste during production. This includes recycling materials, adopting eco-friendly insulation techniques, and applying technologies that extend the lifespan of each product. Such initiatives not only benefit the environment but also align with the growing demand for responsible energy usage worldwide.

For businesses seeking reliable suppliers, understanding the values behind manufacturing practices is just as important as reviewing technical specifications. A facility that emphasizes quality, customization, safety, and sustainability can provide long-term value and stability for its partners. This makes careful supplier selection an essential step for companies planning to integrate transformers into their projects.

In summary, transformer production represents a balance between technology, craftsmanship, and responsibility. Factories in this sector continue to advance by adopting modern methods while remaining focused on safety and efficiency. For organizations searching for dependable products, exploring established facilities provides confidence in both performance and support for future requirements.

To learn more about available products and solutions, you can visit https://www.nbcbdz.com/product/