The global Food Antifoaming Agents Market is experiencing robust growth, fueled by rising demand for processed foods, increased production efficiency needs, and the development of eco-friendly formulations. Food antifoaming agents—critical additives that prevent foam formation during food and beverage processing—are gaining increasing importance across the food industry.

As consumer expectations for high-quality, consistent, and safe food products continue to rise, manufacturers are turning to advanced food processing aids to maintain quality and operational efficiency. The use of food-grade antifoaming agents ensures smooth production, minimizes waste, and enhances the overall stability and texture of final products.

Market Overview

The food industry’s growing focus on product quality, hygiene, and production optimization is propelling the demand for food antifoaming agents. These additives, commonly referred to as defoamers, are vital in reducing foam formation that can disrupt production, affect filling accuracy, and compromise product quality.

In recent years, increased automation and technological advancement within the food processing sector have created an urgent need for consistent process control. Antifoaming agents help manufacturers maintain seamless operations by mitigating foam-related challenges during mixing, fermentation, pasteurization, bottling, and packaging.

Furthermore, the trend toward clean-label and sustainable food ingredients is influencing manufacturers to develop plant-based, biodegradable, and silicone-free alternatives, creating new opportunities across global markets.

Segmentation by Type

The Food Antifoaming Agents Market can be segmented by type into oil-based, silicone-based, water-based, and other formulations. Each segment offers distinct advantages suited to specific industrial requirements and food processing environments.

Oil-Based Antifoaming Agents

Oil-based formulations, typically composed of vegetable or mineral oils, are widely used due to their cost-effectiveness and versatility. These agents are particularly useful in processing edible oils, fats, and fried foods where foam control is essential for maintaining purity and yield.

Silicone-Based Antifoaming Agents

Silicone-based antifoaming agents represent one of the most widely adopted types in the market. They deliver excellent foam suppression efficiency at low concentrations and maintain stability under high-temperature conditions. Their superior performance and compatibility make them ideal for use in beverages, dairy processing, and fermentation-based food applications.

Water-Based Antifoaming Agents

Water-based agents have become increasingly popular due to their eco-friendly and residue-free nature. They are primarily used in aqueous systems such as soft drinks, fruit juices, and other water-based food products. The ease of application and compatibility with clean-label formulations make water-based defoamers a preferred choice for sustainable food production.

Others

The “others” segment includes a variety of emerging and customized antifoaming formulations, often derived from natural and bio-based materials. These are developed to meet the growing consumer demand for organic, non-synthetic food additives and align with regulatory standards promoting safer ingredient usage.

Segmentation by Application

The application scope of food antifoaming agents spans multiple segments of the food and beverage industry, each with unique processing challenges and quality demands.

Bakery and Confectionery

Foam control plays a crucial role in the production of baked goods and confectioneries. Antifoaming agents are used in dough mixing, syrup preparation, and batter processing to prevent unwanted foam, ensuring consistent texture, volume, and taste. In confectionery manufacturing, foam suppression helps achieve smoother finishes and higher-quality products.

Dairy and Frozen Desserts

The dairy industry is one of the largest consumers of food antifoaming agents. Foam generated during pasteurization, homogenization, and fermentation can hinder processing efficiency and affect product uniformity. Antifoaming agents ensure optimal texture and smoothness in products such as cheese, yogurt, ice cream, and milk-based beverages.

Oils and Fats

In edible oil and fat refining processes, foam can disrupt purification and reduce yield. Antifoaming agents play a crucial role in degumming, bleaching, and deodorization stages, ensuring stable processing and improved product clarity. Their use enhances production efficiency while minimizing losses during processing.

Beverages

The beverage sector relies heavily on foam control, particularly during carbonation, fermentation, and bottling operations. Excessive foaming can lead to spillage, reduced filling efficiency, and quality inconsistencies. From soft drinks and fruit juices to beers and plant-based beverages, antifoaming agents ensure smooth production and improved product presentation.

Others

Other applications include sauces, soups, ready-to-eat meals, and processed foods where foam management ensures production consistency and quality. Customized antifoaming formulations cater to these specialized uses, providing flexibility to food manufacturers across categories.

Geographical Insights

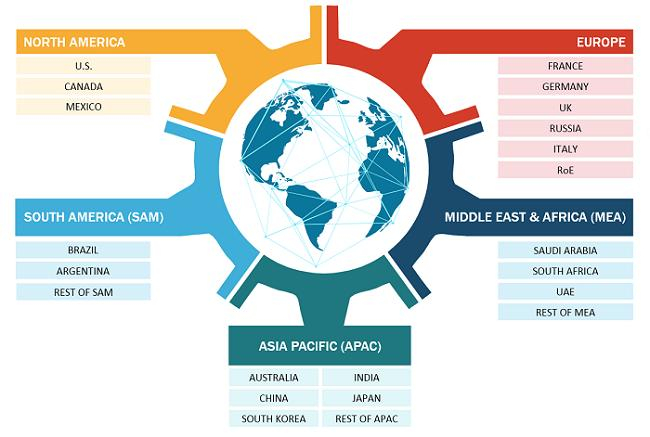

The global Food Antifoaming Agents Market demonstrates diverse growth trends across major regions, including North America, Europe, Asia Pacific, and South and Central America.

North America

North America remains one of the most established markets for food antifoaming agents, supported by a mature food processing sector and strong regulatory oversight. Manufacturers in the United States and Canada continue to adopt innovative solutions to enhance efficiency and maintain compliance with safety standards. The high consumption of convenience foods and beverages further drives regional demand.

Europe

Europe’s market is shaped by its stringent food safety regulations and growing consumer preference for clean-label and sustainable ingredients. Manufacturers across the region are increasingly investing in bio-based and natural defoaming formulations to align with environmental and health-conscious trends. Countries such as Germany, France, and the United Kingdom are at the forefront of adopting these advancements.

Asia Pacific

The Asia Pacific region is witnessing the fastest expansion, fueled by rapid industrialization, population growth, and urbanization. Rising disposable incomes and increasing demand for processed and packaged foods are accelerating food production activities across China, India, Japan, and Southeast Asia. Local and international manufacturers are expanding operations in the region to capitalize on the growing demand.

South and Central America

South and Central America represent emerging markets with promising growth potential. The region’s expanding dairy, beverage, and edible oil industries are driving the adoption of antifoaming agents. Brazil, Argentina, and Mexico are key contributors, with multinational companies entering partnerships and distribution agreements to strengthen market presence.

Key Market Trends

-

Sustainability and Clean Labeling:

Manufacturers are investing in plant-based and biodegradable defoaming agents to meet global sustainability goals and consumer demand for natural ingredients. -

Technological Innovation:

The development of high-efficiency, low-residue antifoaming formulations is improving performance and reducing production costs across industries. -

Regulatory Compliance:

Adherence to food safety standards is driving the shift toward high-purity, food-grade formulations that ensure safety and quality. -

Expansion in Emerging Markets:

Increasing food production capacity in Asia Pacific and Latin America offers significant growth opportunities for both local and international players. -

Collaborations and Product Launches:

Companies are focusing on partnerships, acquisitions, and R&D to strengthen their market position and expand their product portfolios.

Future Outlook

The future of the global Food Antifoaming Agents Market is shaped by innovation, regulation, and sustainability. As food production systems evolve, manufacturers are expected to embrace new technologies that enhance efficiency and minimize environmental impact. The demand for natural, allergen-free, and multifunctional defoamers will continue to rise, creating new avenues for growth and product differentiation.

With consumer awareness about product quality and safety increasing worldwide, the need for high-performing and regulatory-compliant antifoaming solutions will remain strong. The market is poised for steady growth as both global and regional players invest in sustainable innovation and expand their reach in emerging economies.

About the Report

The Food Antifoaming Agents Market Report provides comprehensive insights into market segmentation, growth drivers, challenges, and competitive dynamics. Covering detailed analysis by type , application , and geography , the report offers valuable guidance to stakeholders aiming to understand evolving market trends and opportunities.

Also Available in: