The global Super Abrasive Market is experiencing accelerated growth as industries worldwide embrace high-precision manufacturing processes that demand ultra-hard, efficient, and reliable tooling materials. Super abrasives—primarily Diamond and Cubic Boron Nitride (CBN) —are increasingly becoming indispensable across multiple sectors, from automotive and aerospace to electronics and construction .

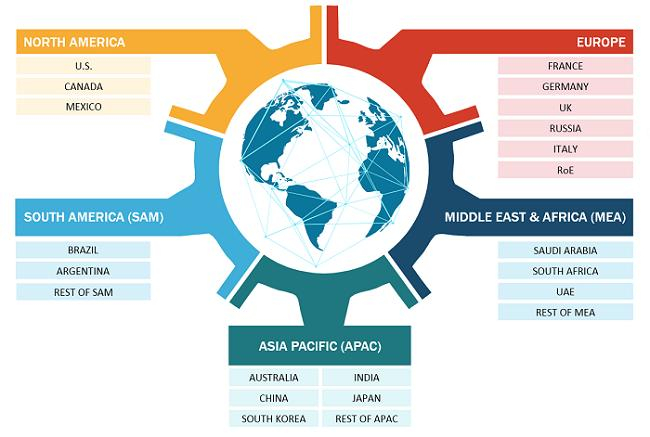

A new comprehensive industry analysis covering the market by Material Type (Diamond, CBN), End-User Industry (Construction, Transportation, Oil & Gas, Electrical & Electronics, Others), Application (Powertrain, Bearing, Gear, Tool Grinding, Turbine, and Others), and Geography (North America, Europe, Asia Pacific, and South & Central America) reveals the trends shaping the future of this fast-evolving sector.

Market Overview

The Super Abrasive Market is witnessing consistent expansion due to the global shift toward high-precision, durable, and automated production systems. Industries are increasingly relying on advanced grinding and cutting solutions capable of handling ultra-hard materials such as composites, ceramics, hardened steels, and advanced alloys.

The superior hardness, thermal stability, and extended tool life offered by diamond and CBN abrasives have positioned them as key materials for next-generation manufacturing environments. Market growth is further supported by technological innovation in bonding systems, tool design, and digital monitoring for performance optimization.

Material Type Analysis

Diamond Super Abrasives continue to dominate the market, holding a significant share owing to their unparalleled hardness and efficiency in machining non-ferrous metals, composites, and ceramics. Diamond abrasives are widely used in electronics, glass processing, precision optics, and automotive component manufacturing, where smooth finishes and micron-level accuracy are essential.

On the other hand, Cubic Boron Nitride (CBN) is rapidly gaining market share, especially for ferrous metal machining applications. Its excellent thermal and chemical stability makes it ideal for cutting hardened steels, gears, and engine components. Analysts expect the CBN segment to grow at a higher rate than diamond in the coming decade, driven by increasing demand in powertrain, aerospace, and heavy machinery manufacturing.

Together, diamond and CBN form the backbone of the modern precision tooling industry, each serving distinct applications that are vital to industrial innovation and efficiency.

End-User Industry Insights

The transportation industry, particularly the automotive sector, represents the largest end-user of super abrasives. The global transition to electric vehicles (EVs) has created new machining challenges requiring materials that can deliver superior precision on lightweight metals and hard composite materials. Super abrasives are now integral to manufacturing EV motors, batteries, and precision drivetrains.

The construction industry is another key user, employing super abrasives in the cutting, drilling, and grinding of stone, concrete, and glass for architectural and infrastructural projects. Rapid urbanization and infrastructure development across Asia Pacific and the Middle East have significantly boosted demand in this segment.

In oil and gas, super abrasives are utilized for drilling and maintenance tools designed to withstand extreme environments, while in the electrical and electronics sector, diamond abrasives play a crucial role in wafer slicing, lens shaping, and circuit fabrication. As semiconductor and consumer electronics production expands, this segment is expected to exhibit one of the fastest growth rates.

Other emerging end-users include medical device manufacturing, aerospace turbine production, and industrial tooling, where extreme precision and material durability are critical.

Application Breakdown

By application, powertrain components remain the largest segment, encompassing crankshafts, camshafts, and transmission parts that demand ultra-smooth finishes and dimensional consistency. As automakers focus on improving fuel efficiency and reliability, super abrasives have become essential for fine grinding and polishing operations.

Bearing and gear manufacturing represent other major application areas. Super abrasives provide unmatched consistency and durability in producing high-precision gears and bearings used in both traditional and electric vehicles, as well as in industrial machinery.

The tool grinding segment also commands a strong position, as manufacturers of carbide and high-speed steel tools increasingly rely on diamond and CBN abrasives for sharpening and finishing. In turbine manufacturing, particularly for aerospace and power generation, the ability to grind and polish high-temperature alloys and ceramic coatings has made super abrasives indispensable.

Overall, the market’s growth across these applications underscores the expanding role of advanced materials and the demand for longer-lasting, high-performance tools in manufacturing operations.

Geographical Insights

Asia Pacific: The Growth Engine

Asia Pacific currently dominates the global super abrasive market, accounting for the largest revenue share. Countries such as China, Japan, South Korea, and India are at the forefront of industrial production, automotive manufacturing, and semiconductor fabrication—all of which heavily depend on precision tooling.

Government initiatives promoting local manufacturing and rapid industrialization have amplified regional demand. Furthermore, infrastructure expansion and the booming EV sector in Asia are expected to sustain the region’s leadership position through 2030.

North America: Hub of Technological Innovation

North America continues to drive technological innovation in the super abrasive market. The region’s strong aerospace, defense, and advanced automotive sectors prioritize high-value, performance-driven tools. The United States, in particular, is witnessing increased adoption of smart manufacturing systems and digital grinding solutions, further boosting the use of CBN and diamond-based tools.

Europe: Precision Engineering Leadership

Europe remains a powerhouse in precision engineering and automotive excellence, with Germany, Switzerland, and the UK serving as key markets. The focus on sustainable manufacturing, high-quality machining, and advanced automation ensures continued demand for premium-grade super abrasives.

South & Central America: Emerging Potential

While still a smaller market, South and Central America are witnessing growing industrial activity. Expanding infrastructure development and increasing local manufacturing capabilities in Brazil, Argentina, and Mexico are expected to drive future growth opportunities in the region.

Market Drivers and Challenges

Key Growth Drivers:

-

Rising demand for precision machining and surface finishing in automotive, aerospace, and electronics industries.

-

Expansion of the EV and semiconductor markets, creating new requirements for high-precision cutting and grinding tools.

-

Growing adoption of automation and Industry 4.0 technologies that demand durable, sensor-enabled super abrasive solutions.

-

Continuous R&D leading to improved synthetic diamond and CBN production and innovative bonding materials.

Key Challenges:

-

High cost of super abrasive materials compared to conventional abrasives.

-

Supply chain constraints related to raw materials and energy-intensive manufacturing processes.

-

Rapid evolution of substrate materials (new alloys, ceramics, composites) that necessitate constant tooling innovation.

Despite these challenges, the superior performance and cost-efficiency benefits of super abrasives over their lifespan continue to make them the preferred choice in precision manufacturing environments.

Future Outlook

Looking ahead, the global Super Abrasive Market is projected to maintain a strong upward trajectory. Growth will be driven by the convergence of advanced materials, smart machining systems, and the global shift toward sustainable, high-precision production.

Manufacturers are expected to focus on developing customized super abrasive solutions tailored for emerging applications such as EV motor components , semiconductor wafers , and aerospace turbines . Strategic partnerships with OEMs and continuous investment in R&D will remain critical to sustaining competitiveness.

As industries demand higher productivity, better surface quality, and lower operational costs, super abrasives are set to play a pivotal role in shaping the next generation of industrial and technological progress.

About the Report

The Super Abrasive Market report provides a comprehensive overview of the industry, analyzing segmentation by Material Type, End-User Industry, Application, and Geography , with insights into market dynamics, emerging trends, and strategic recommendations for stakeholders. The study highlights how technological innovation and shifting industrial priorities are redefining global demand for ultra-hard materials.

Also Available in: