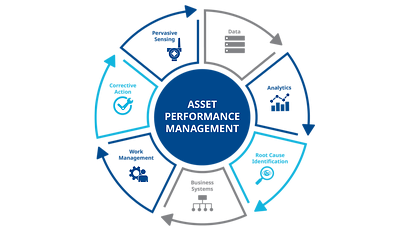

Current Asset Performance Management Market Trends indicate revolutionary changes with market progression from USD 4.37 billion to USD 10 billion, advancing at 7.82% CAGR during 2025-2035. Artificial intelligence and machine learning dominate trend discussions with predictive algorithms continuously improving through operational data. Digital twin technology creates virtual asset replicas enabling simulation and predictive analysis without production disruption. Edge computing deployment processes sensor data locally reducing latency for time-critical maintenance decisions. Cloud-native architectures provide scalability and accessibility supporting distributed asset management. Prescriptive analytics evolve beyond failure prediction to recommend specific maintenance actions and optimal timing. Condition-based monitoring replaces fixed-interval maintenance with real-time assessments driving efficiency. Mobile-first design ensures field technicians access critical information regardless of location. Sustainability integration measures environmental impact of maintenance decisions guiding greener operations.

Technology trends reshape APM capabilities and deployment architectures across industrial sectors. IoT sensor proliferation generates massive data volumes requiring sophisticated analytics and storage solutions. Computer vision enables automated equipment inspection identifying issues invisible to traditional sensors. Natural language processing extracts insights from maintenance logs and technical documentation. Blockchain provides immutable maintenance records and spare parts provenance verification. 5G connectivity enables real-time monitoring of mobile assets and remote facilities. Quantum computing exploration addresses complex optimization problems in maintenance scheduling. Augmented reality overlays guide technicians through maintenance procedures improving accuracy and efficiency. Robotic process automation handles routine data collection and reporting tasks.

Business model trends influence APM adoption and vendor strategies globally. Outcome-based pricing ties costs to realized benefits aligning vendor and customer interests. Managed service offerings provide comprehensive APM capabilities without internal expertise requirements. Platform ecosystems enable third-party applications expanding functionality beyond core vendors. Subscription models shift from capital to operational expenditure improving financial accessibility. Industry-specific solutions address unique requirements in power, oil and gas, manufacturing, and transportation. SME-focused offerings democratize APM access previously limited to large enterprises. Hybrid deployment models balance cloud benefits with on-premises security and control requirements. Consulting integration combines software with expertise accelerating value realization and optimization.

Operational trends reflect changing maintenance philosophies and organizational structures. Predictive maintenance adoption accelerates replacing reactive and preventive approaches with data-driven strategies. Centralized monitoring enables remote oversight of distributed assets from consolidated operation centers. Reliability engineering integration ensures design improvements incorporate operational performance insights. Cross-functional collaboration breaks silos between maintenance, operations, and engineering departments. Skills development programs address analytics and data science requirements for APM success. KPI evolution measures asset health and maintenance effectiveness beyond traditional metrics. Continuous improvement cultures leverage APM insights for ongoing optimization and innovation. Sustainability focus considers lifecycle environmental impact in maintenance and replacement decisions.

Explore Our Latest Trending Reports:

Indoor Farming Technology Market