Introduction: Importance of Environmental Reliability

In modern electronic applications, connectors often face challenging environments, including high humidity, elevated temperatures, and corrosive atmospheres. The WTB Wire to Board Connector is specifically engineered to maintain reliable electrical and mechanical performance under such conditions. Understanding how it performs in harsh environments is essential for designers, engineers, and manufacturers who require dependable connectivity for industrial, automotive, or outdoor electronics.

Material Selection and Corrosion Resistance

The durability of a WTB Wire to Board Connector in humid or corrosive environments begins with material selection. Contacts are often plated with corrosion-resistant metals such as gold or tin to prevent oxidation and maintain low contact resistance. The connector housing typically uses high-quality thermoplastics or engineered polymers, which provide chemical resistance and structural integrity under exposure to moisture, acids, or salts. These materials ensure that the connector remains reliable even after prolonged exposure to aggressive environmental conditions.

High-Temperature Performance

Electronic devices can generate heat during operation, or they may operate in naturally hot environments. The WTB Wire to Board Connector is designed to withstand elevated temperatures without deforming or losing contact integrity. Thermally stable plastics and high-temperature-rated metal alloys allow the connector to maintain its shape and functionality. High-temperature performance also ensures that insulation resistance remains strong and that mechanical locking features do not degrade over time, preserving the safety and reliability of the connection.

Humidity and Moisture Resistance

Moisture can cause short circuits, corrosion, and electrical leakage. The WTB Wire to Board Connector is designed with tight contact tolerances, secure locking mechanisms, and protective insulating materials to resist the effects of high humidity. Some connectors may also include sealing features, such as gaskets or coatings, to prevent water ingress, ensuring that the electrical connection remains stable and reliable even in damp conditions.

Testing and Reliability Standards

To verify performance under harsh environments, manufacturers conduct rigorous environmental testing on the WTB Wire to Board Connector. This includes exposure to high temperatures, salt spray, humidity chambers, and thermal cycling. Testing ensures that contact resistance, insulation resistance, and mechanical integrity remain within specified limits. Compliance with standards such as IEC, UL, or RoHS provides confidence that the connector will perform reliably in demanding applications.

Applications and Practical Considerations

The robust environmental performance of the WTB Wire to Board Connector makes it suitable for a wide range of applications, including automotive electronics, industrial machinery, outdoor devices, and consumer electronics exposed to moisture or heat. Designers should still consider proper installation, alignment, and recommended torque specifications to maximize the connector’s reliability. Choosing connectors with the appropriate environmental ratings ensures long-term durability and safety.

Durable and Reliable Under Harsh Conditions

In conclusion, the WTB Wire to Board Connector demonstrates excellent reliability in humid, high-temperature, and corrosive environments. Its corrosion-resistant contacts, thermally stable housing, and secure mechanical design allow it to maintain electrical and mechanical performance under demanding conditions. For engineers and designers seeking dependable connectors in challenging environments, this connector provides a durable, high-performance solution that ensures stable and safe connections over the long term.

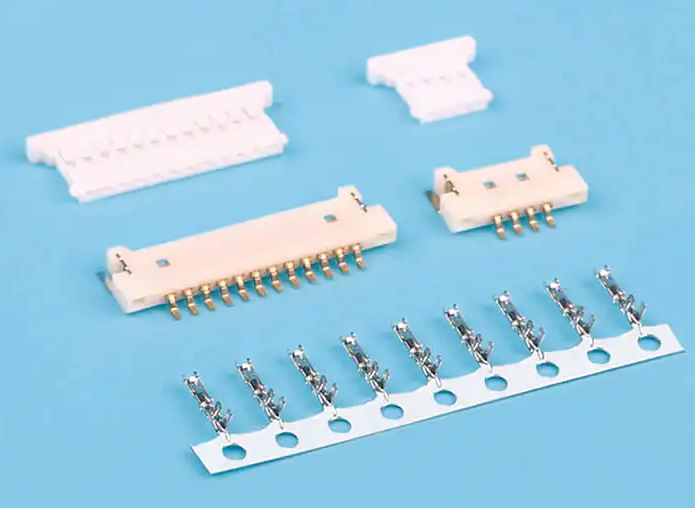

1、CKT: 2Pin to 26Pin

2、Current rating: 1A AC/DC

3、Voltage rating(max): 50V, AC/DC

4、Working Temperature: -25°C~+85°C,

(Including temperature rise in applying electrical current)

5、Contact resistance: Initial value S20mΩ

After environmental testing≤30mΩ

6、Insulation resistance: 2100MΩ

7、Withstand voltage: 500VAC(rms)

8、Applicable wire: AWG #32 to #28

9、Applicable PCB board thickness: 1.6mm to 2.0mm