In the pharmaceutical industry, oral liquid preparations are one of the most widely used dosage forms. From small-volume 2ml health solutions to 50ml therapeutic preparations, the demand for accuracy and consistency is extremely high. Yet, many enterprises still face persistent challenges:

· How to ensure every bottle meets compliance standards?

· How to balance inspection accuracy with production efficiency?

· How to reduce manual errors and inspection costs while maintaining stability in high-volume production?

This is where the Oral Liquid Inspection Machine becomes a valuable tool. Designed as a universal testing solution, it brings automation, precision, and reliability to oral liquid quality control.

Industry Pain Points

Manual inspection of oral liquid bottles has long been a bottleneck. Human operators face fatigue, subjective judgment, and limited detection speed. Even semi-automated solutions often struggle with:

· High error rates in detecting tiny particles or scratches.

· Low efficiency when scaling up production.

· Quality risks due to inconsistent inspection standards.

For enterprises, these pain points not only impact product quality but also bring risks in compliance, recalls, and additional operational costs.

How the Oral Liquid Inspection Machine Works

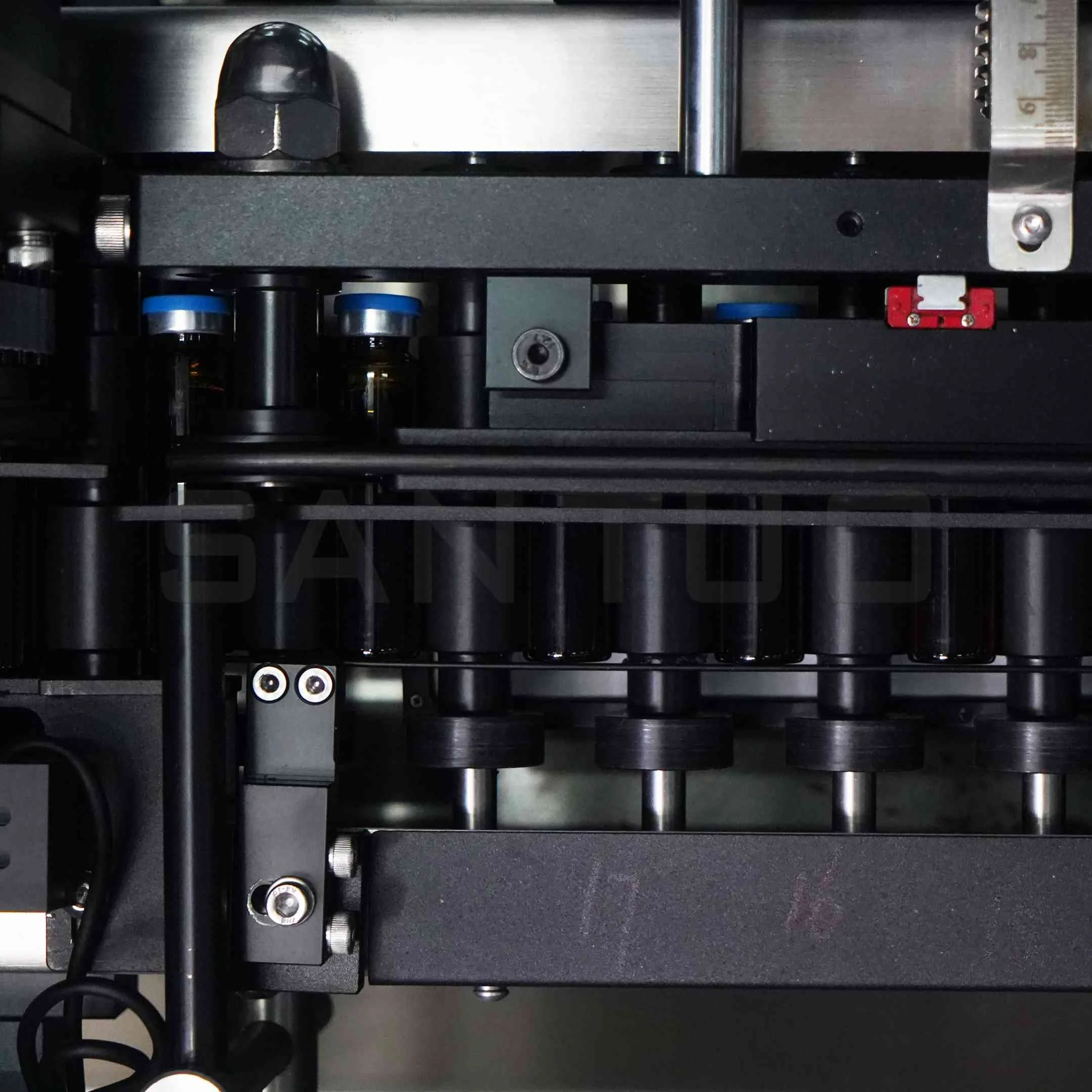

The system adopts a modular design to accommodate a wide range of bottle sizes (2ml–50ml) and integrates seamlessly into existing production lines. Its workflow can be broken down into several stages:

· Vertical-to-Horizontal Bottle Transition

Screw-based bottle separation ensures a stable transfer from vertical to horizontal posture, preventing bottle compression and misalignment.

· High-Speed Vision Inspection

A multi-angle vision system detects defects such as scratches, cracks, or suspended particles in the liquid.

· Stable Conveying

Horizontal roller chains combined with reference positioning improve accuracy in liquid level detection.

· Smart Rejection System

Pneumatic rejection linked to detection results ensures faulty products are removed without mis-rejecting good ones.

· Compact and Flexible Integration

The equipment can run independently or be docked into full-scale production lines, reducing installation space and manpower requirements.

Key Benefits for Enterprises

1. Higher Detection Accuracy

Identifies minute foreign particles, cracks, or level deviations with precision.

2. Improved Compliance

Helps enterprises meet GMP and international quality standards consistently.

3. Reduced Loss and Downtime

Intelligent rejection avoids unnecessary waste of qualified products, while shutdown protection minimises broken bottle incidents.

4. Operational Efficiency

Speeds up inspection while lowering labour dependency, achieving long-term cost savings.

5. Easy Product Changeover

Modular parts and tool-free disassembly simplify changeover between different bottle specifications.

Practical Applications

The Oral Liquid Inspection Machine is particularly valuable for:

· Pharmaceutical enterprises manufacturing high-volume oral solutions.

· Contract manufacturing organisations (CMOs) that need flexible, multi-specification inspection systems.

· Export-focused companies aiming to meet stricter overseas compliance and safety requirements.

Conclusion

For pharmaceutical enterprises, investing in an Oral Liquid Inspection Machine is not just about automation—it’s about ensuring compliance, reducing risks, and securing long-term efficiency. By combining advanced vision inspection with intelligent rejection and stable conveying, this equipment addresses industry pain points directly.

In a market where product quality defines competitiveness, adopting a reliable inspection system is a strategic move for sustainable growth.

Learn more about the Oral Liquid Inspection Machine and how it can fit into your production line.