How Kerb Ramp Manufacturers Enhance Safety and Accessibility in Modern Environments

The Growing Importance of Kerb Ramps Today

Kerb ramps have become essential components in both public and commercial spaces. They support smooth transitions between different height levels, benefiting pedestrians, wheelchair users, delivery workers, and vehicles. Behind each reliable ramp is a skilled Kerb Ramp Manufacturer that understands how to balance strength, accessibility, and long-term durability. As urban environments evolve, the role of professional manufacturers becomes increasingly important.

Building Ramps with Strong and Long-Lasting Materials

Durability starts with the choice of raw materials. High-quality ramps are typically produced using heavy-duty rubber, high-density plastic, composite blends, or reinforced compounds. These materials are selected for their resistance to cracking, compression, and weather damage. Whether exposed to traffic, sunlight, or moisture, well-designed ramps remain stable for years. By using industrial-grade materials, a professional Kerb Ramp Manufacturer ensures that each product can handle everyday pressure without deformation.

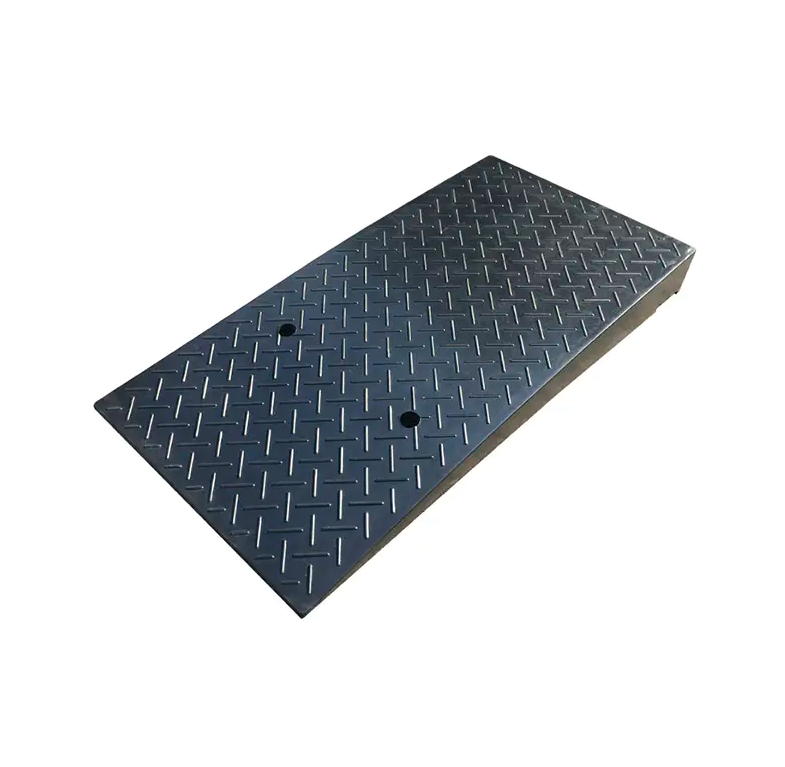

Focusing on Anti-Slip Design for User Safety

Safety is a primary goal in ramp engineering. To achieve this, manufacturers include detailed anti-slip textures, raised surfaces, and friction-enhancing patterns. These elements help prevent slipping, even when the ramp is placed in areas with rain, oil, or constant movement. Stable bases and reinforced edges also contribute to preventing unwanted ramp shifting. All these design features help users move confidently across height differences with minimal risk.

Tailoring Ramps to Different Installations and Industries

Modern ramps are used in a wide range of environments—from sidewalks and residential communities to warehouses, retail areas, logistic hubs, and industrial facilities. Each setting has its own needs, and manufacturers often offer customization options to meet them. These may include custom dimensions, color markings, reflective strips, or higher load capacities for heavy equipment. An experienced Kerb Ramp Manufacturer works closely with buyers to design solutions that fit both functional and safety requirements.

Using Advanced Manufacturing Technology for Precision

Ramp reliability depends greatly on production accuracy. Manufacturers use technology such as injection molding, compression molding, and CNC cutting to ensure consistent density and structure. These automated processes minimize human error and ensure that each ramp maintains the same quality standards. Stress tests, load testing, and environmental exposure simulations help verify that the final product can withstand real-world conditions without failure.

Improving Visibility for Safer Traffic Flow

Visibility is especially important in busy or low-light environments. To improve awareness, manufacturers often incorporate bold colors, reflective elements, or warning symbols into their ramps. These visual cues alert pedestrians and drivers to height changes, reducing unexpected accidents. Enhancing visibility is one of the most effective yet simple ways manufacturers improve overall safety.

Developing Portable and Easy-to-Install Solutions

Many ramps serve temporary or mobile purposes, such as during events, deliveries, or construction work. For this reason, manufacturers design ramps that are lightweight, portable, and easy to reposition. Built-in handles, modular structures, and well-balanced weight distribution make transportation simpler. This flexibility allows ramps to be used across multiple locations without needing tools or complex installation steps.

Creating Value Through Engineering and Practical Design

Long-lasting kerb ramps result from thoughtful engineering, material innovation, and strict quality control. A dependable Kerb Ramp Manufacturer focuses not only on safety but also on reducing long-term maintenance needs. Well-designed ramps help improve accessibility, enhance workplace efficiency, and support safer public environments. As technology progresses, manufacturers continue to develop better solutions that meet the growing demands of modern infrastructure.