Introduction to Blade Wear in Angle Cutting

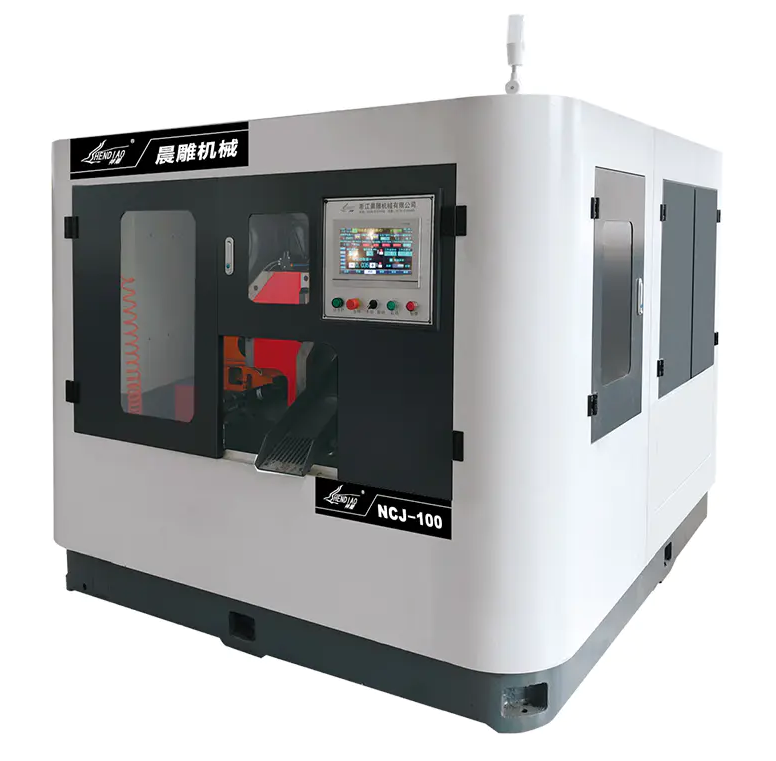

A Fully Automatic Angle Cutting Band Saw Machine is widely used in industrial settings to cut metal bars, tubes, and profiles at precise angles. One of the most critical factors affecting cut quality is the condition of the saw blade. Over time, blades naturally wear down due to friction, heat, and repeated engagement with the workpiece. Understanding how blade wear impacts cutting performance is essential for maintaining accuracy, surface finish, and overall productivity in high-precision applications.

Mechanics of Blade Wear

Blade wear occurs as the cutting edges lose their sharpness, which reduces their ability to shear material cleanly. In angle cutting operations, any deterioration in the blade teeth directly affects how smoothly the metal is cut along the intended angle. Worn teeth require greater force to cut, causing vibration, uneven material removal, and deviations from the desired angle. This can lead to inaccurate cuts, excessive burrs, and rough surfaces that may require secondary finishing operations.

Impact on Cutting Accuracy

Cutting accuracy is highly sensitive to blade condition. A sharp blade ensures consistent engagement with the workpiece, maintaining precise angles and dimensions. As the blade wears, it may produce minor deflection or wander during cutting, particularly in long or thick metal profiles. Even small deviations can accumulate when cutting multiple pieces, resulting in parts that fail to meet tolerance specifications. Maintaining sharp, well-conditioned blades is essential for ensuring that the fully automatic system delivers reliable, repeatable cuts.

Surface Finish and Edge Quality

The quality of the cut surface is closely linked to blade sharpness. A worn blade tends to tear or grind the metal rather than slice cleanly, leaving rough edges and burrs. This not only affects the aesthetic appearance but also increases the need for post-cutting operations such as grinding or deburring. High-speed angle cutting amplifies these effects, as worn teeth cannot manage heat and friction efficiently, further compromising edge quality.

Increased Machine Load and Vibration

Blade wear also affects the mechanical load on the saw. Dull blades require more torque and force from the machine to penetrate the workpiece. This increases strain on the motor, transmission system, and guiding mechanisms. Excessive vibration can occur when the blade struggles to maintain smooth motion, which negatively impacts both cut quality and machine longevity. Proper monitoring of blade condition is therefore critical to protect the machine and maintain consistent performance.

Productivity and Operational Efficiency

Worn blades reduce cutting efficiency, forcing slower feed rates to avoid damage or poor cuts. This increases cycle time and reduces overall productivity, especially in fully automated production environments. Frequent blade replacement or sharpening may be necessary, but neglecting this maintenance can lead to downtime, scrap material, and higher operational costs.

Preventive Measures and Maintenance

To mitigate the effects of blade wear, operators should implement regular inspection routines, monitor cutting performance, and replace or recondition blades as needed. Proper selection of blade type and tooth geometry for the specific material also extends blade life. Fully automatic machines often feature blade monitoring systems or load sensors that help detect excessive wear before it compromises cutting quality.

Blade wear has a direct and significant impact on the cutting quality of a Fully Automatic Angle Cutting Band Saw Machine. It affects cutting accuracy, surface finish, machine load, and overall productivity. By maintaining sharp blades, monitoring wear, and selecting appropriate blade types for specific materials, operators can ensure consistent, precise, and efficient angle cutting. Understanding the relationship between blade condition and performance is essential for achieving high-quality results in industrial metal cutting applications.