In today's industrial environment, stable energy conversion remains a quiet but essential foundation for countless systems. Within this landscape, the EI Transformer Factory concept represents a manufacturing mindset centered on consistency, adaptability, and process awareness, while the brand Nbcbdz reflects a practical approach to meeting diverse operational requirements. Together, they frame a discussion not about spectacle, but about thoughtful production, technical alignment, and sustainable cooperation across industries.

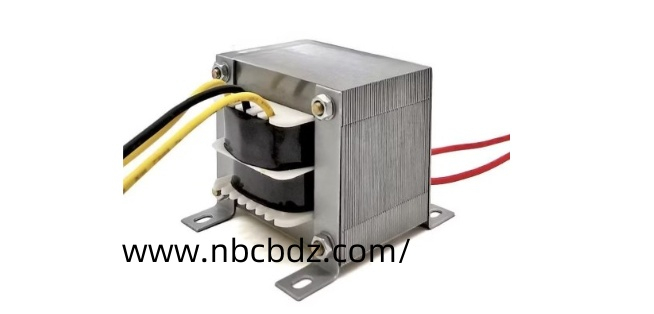

Transformers built under the EI structure are often selected for their balanced design philosophy. Their core configuration supports steady electromagnetic performance while allowing flexibility in form and application. This makes them suitable for equipment where space, reliability, and predictable operation are all considerations. From control systems to everyday industrial devices, such transformers quietly support workflows without demanding constant attention.

A key element behind their relevance lies in manufacturing discipline. Careful material selection, attention to winding methods, and consistent assembly processes help ensure that each unit aligns with expected operating conditions. Rather than focusing on novelty, this approach values repeatable results. For system designers and equipment manufacturers, this predictability simplifies integration and long-term maintenance planning.

Another important aspect is adaptability. Industrial environments vary widely, and power components must accommodate different voltage requirements, environmental conditions, and installation constraints. EI-style transformers can be tailored within defined parameters, enabling engineers to match electrical characteristics with real-world usage scenarios. This flexibility supports a wide range of sectors, from automation to commercial equipment, without overcomplicating design choices.

Beyond technical considerations, communication and cooperation play an equally important role. Clear documentation, responsive coordination, and a shared understanding of project goals help transform manufacturing from a transactional process into a collaborative one. When expectations are aligned early, development cycles become smoother, and outcomes feel more reliable for all parties involved.

Sustainability, in a practical sense, is also part of the conversation. Efficient use of materials, responsible production planning, and designs that encourage long service life contribute to reduced waste over time. While often overlooked, these factors influence both operational cost management and broader environmental responsibility, making them relevant to modern procurement decisions.

As industries continue to evolve, the demand for dependable power components will remain. The value lies not in dramatic claims, but in steady performance, thoughtful design, and manufacturing practices that respect both technical and human factors. These qualities help build trust over time and support systems that function as intended, day after day.

If you are curious about how such manufacturing perspectives translate into real-world solutions, consider taking a quiet moment to browse a space where these ideas come together. A visit to https://www.nbcbdz.com/product/ may offer insights that align with your current projects and spark new possibilities for future collaboration.