The Force Sensor Market has emerged as a critical segment within the broader sensor and instrumentation industry, driven by rapid advancements in automation, robotics, automotive safety systems, and precision manufacturing. Force sensors, which are designed to measure tension, compression, or combined forces applied to an object, play a vital role in ensuring accuracy, safety, and efficiency across multiple industries. As industries increasingly move toward smart manufacturing, digitalization, and connected systems, the relevance of force sensors continues to expand steadily.

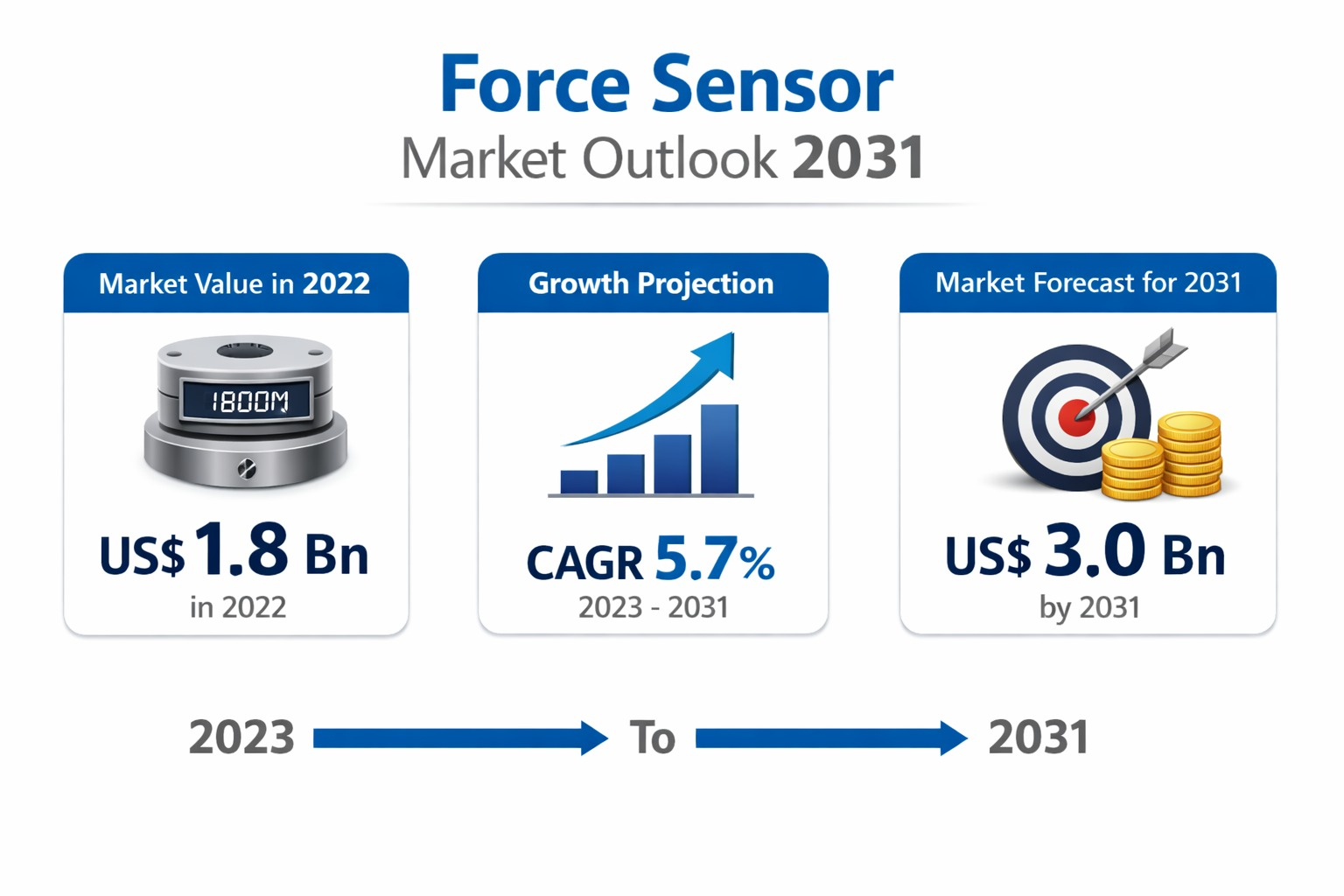

According to industry estimates, the global force sensor market was valued at US$ 1.8 Bn in 2022 and is projected to reach US$ 3.0 Bn by the end of 2031, growing at a compound annual growth rate (CAGR) of 5.7% during the forecast period from 2023 to 2031. This growth trajectory reflects rising demand from automotive production, increasing adoption of industrial robots, and the growing need for precise force measurement in healthcare and aerospace applications.

Market Overview and Introduction

Force sensors are specialized devices used to detect, measure, and monitor forces exerted on a surface or component. These sensors convert mechanical force into measurable electrical signals, enabling real-time monitoring and control. Depending on their design and application, force sensors can measure tension force, compression force, or both, making them highly versatile.

Industries such as automotive, aerospace, medical devices, industrial automation, oil & gas, and consumer electronics rely heavily on force sensors for applications ranging from braking systems and airbag deployment to robotic grip control and material testing. Their compact size, cost-effectiveness, and compatibility with microelectromechanical systems (MEMS) have further broadened their adoption across both large-scale industrial systems and miniature electronic devices.

Force Sensor Market Size and Growth Outlook

The steady expansion of the force sensor market is underpinned by structural shifts in global manufacturing and transportation systems. As industries prioritize safety, efficiency, and automation, force sensors have become indispensable components.

-

Market Size (2022): US$ 1.8 Bn

-

Forecast Value (2031): US$ 3.0 Bn

-

CAGR (2023–2031): 5.7%

This consistent growth reflects sustained investments in advanced manufacturing technologies, increasing vehicle production worldwide, and the rising use of robotics in industrial settings.

Key Market Drivers

Rise in Production of Vehicles

One of the primary growth drivers of the force sensor market is the increasing production of vehicles globally. Force sensors are extensively used in automotive systems such as Anti-lock Braking Systems (ABS), Electronic Stability Control (ESC), airbags, and brake pedal force measurement. These sensors enhance vehicle safety, improve system responsiveness, and support compliance with stringent safety regulations.

In addition, force sensors are applied in engine management systems, oil pressure monitoring, and advanced driver-assistance systems (ADAS). Growing disposable income, rapid urbanization, and increasing consumer preference for personal mobility are boosting vehicle ownership, particularly in emerging economies. Post-pandemic recovery in automotive manufacturing hubs such as China, Japan, and Germany has further strengthened demand for force sensors.

Increase in Adoption of Industrial Robots

The rapid adoption of industrial robots is another major factor accelerating force sensor market growth. Force sensors enable robots to detect applied forces at the wrist or end-of-arm tooling, allowing for precise motion control and safer human-robot collaboration.

In robotic applications, force sensors provide haptic feedback, enable grip force verification, and ensure balance and stability during operations. This capability is essential in industries such as automotive manufacturing, electronics assembly, and logistics. Growth in robot installations, particularly in North America, is significantly contributing to rising demand for advanced force sensing solutions.

Technological Advancements and Market Trends

Integration with IoT and Wireless Connectivity

One of the most notable trends in the force sensor market is the integration of sensors with Internet of Things (IoT) platforms and wireless communication technologies. Smart force sensors enable real-time data transmission, remote monitoring, and predictive maintenance, reducing downtime and improving operational efficiency.

Emergence of Smart Force Sensors

Smart force sensors with embedded signal processing capabilities are gaining traction across industries. These sensors provide real-time feedback, enhanced accuracy, and improved system intelligence. In manufacturing environments, they support condition monitoring and predictive analytics, helping companies optimize production processes and reduce operational costs.

Miniaturization and MEMS-Based Sensors

The increasing adoption of MEMS technology has led to the development of compact, lightweight, and cost-effective force sensors. These sensors are widely used in consumer electronics, medical devices, and wearable technologies, further expanding the market’s application scope.

Market Challenges and Restraints

Despite favorable growth prospects, the force sensor market faces several challenges that could limit its expansion in the coming years.

One of the key challenges is the need for highly accurate and reliable measurements, particularly in sectors such as aerospace, medical devices, and automotive safety systems. Even minor inaccuracies can lead to system failures or safety risks.

Additionally, sensor damage and low sensitivity can result in higher rejection rates during manufacturing, reducing overall output capacity. Rapidly evolving industry requirements also demand continuous innovation, placing pressure on manufacturers to invest heavily in research and development.

Market Segmentation Analysis

By Measurement Type

-

Tension Force Sensors: Used to measure pulling forces, commonly applied in material testing and load monitoring.

-

Compression Force Sensors: Designed to measure pushing forces, widely used in industrial automation and automotive systems.

-

Both (Tension and Compression): These sensors offer versatility and are increasingly preferred for complex applications requiring multi-directional force measurement.

By End-use Industry

-

Automotive: Largest application segment, driven by safety systems and vehicle electronics.

-

Industrial: Includes manufacturing automation, robotics, and material handling.

-

Medical: Used in diagnostic equipment, surgical tools, and rehabilitation devices.

-

Oil & Gas: Applied in drilling operations, pressure monitoring, and load measurement.

-

Aerospace & Defense: Utilized in flight control systems, force feedback, and testing applications.

Regional Outlook

North America – Leading Region

North America held the largest share of the global force sensor market in 2022. The region benefits from a strong presence of automotive manufacturers, oil & gas operations, aerospace & defense companies, and consumer electronics producers.

High investment in research and development, along with the presence of key market players, supports continuous innovation in force sensing technologies. The United States, in particular, stands out as a major automotive and electronics manufacturing hub, driving consistent demand for force sensors.

Other Regions

-

Europe: Driven by automotive innovation, industrial automation, and aerospace applications.

-

Asia Pacific: Expected to witness strong growth due to expanding manufacturing activities in China, Japan, South Korea, and India.

-

Middle East & Africa and South America: Moderate growth supported by oil & gas and industrial development.

Competitive Landscape and Key Players

The force sensor market is moderately fragmented, with several global and regional players competing on the basis of technology, accuracy, reliability, and application-specific solutions. Leading companies are focusing on product innovation, strategic partnerships, and expansion of their product portfolios.

Some of the prominent players operating in the global force sensor market include:

-

Honeywell International Inc.

-

TE Connectivity

-

Kistler Group

-

FUTEK Advanced Sensor Technology

-

Dytran Instruments Incorporated

-

Flintec Inc.

-

Tekscan Inc.

-

Lorenz Messtechnik GmbH

-

ME-Meßsysteme GmbH

-

Sherborne Sensors

These companies are investing heavily in R&D to develop next-generation force sensors tailored for emerging applications such as electromechanical braking systems and collaborative robots.

Recent Developments in the Force Sensor Market

-

In October 2022, Sensata Technologies introduced a new brake pedal force sensor for electromechanical brakes, aimed at improving braking safety and performance.

-

In April 2023, Kistler Fiber Technology expanded its R&D footprint by acquiring additional research space in the United Kingdom.

-

Several manufacturers have introduced advanced load cells, force transducers, and torque measurement solutions to cater to diverse industrial requirements.

Future Outlook and Opportunities

The future of the force sensor market looks promising, supported by long-term trends such as automation, electrification of vehicles, and digital transformation of industries. Growing adoption of electric vehicles, expansion of smart factories, and increasing use of robots in healthcare and logistics are expected to create new growth opportunities.

Furthermore, advancements in materials science, sensor fusion, and artificial intelligence are likely to enhance force sensor performance and broaden their application scope. Companies that focus on innovation, customization, and integration with digital platforms are expected to gain a competitive edge in the evolving market landscape.