A Magna Tiles Factory serves as the foundation for producing educational and recreational building sets used by children and hobbyists. While consumers often focus on design appeal or magnet strength, the operations behind a factory influence product consistency, safety, and overall usability. Understanding these processes provides insight into how manufacturers maintain steady performance across batches.

At its core, a Magna Tiles Factory transforms raw materials into interlocking plastic and magnetic tiles that meet safety and playability standards. The production process begins with material selection. High-quality polymers, magnetic components, and durable coatings are chosen for stability and non-toxicity. Instead of relying on broad claims of durability, many factories perform controlled tests to assess flexibility, color retention, and magnetic alignment.

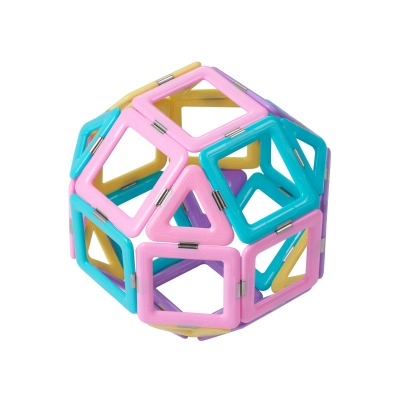

Design development is another crucial aspect of a Magna Tiles Factory. Engineers and designers collaborate to ensure that each tile fits correctly with others, that edges are smooth, and that magnets are properly encased. Considerations include both the physical safety of children and the tactile experience of construction play. Modular designs allow a wide range of configurations without compromising assembly consistency.

Injection molding is typically a core process in a Magna Tiles Factory. Molds are carefully maintained and calibrated to ensure that each tile has uniform dimensions and surface quality. During production, technicians monitor temperature, pressure, and cooling times to reduce defects. These precise processes help maintain uniformity across multiple production runs, supporting reliable assembly for end users.

Magnetic components are integrated after molding, often using automated assembly lines. A responsible Magna Tiles Factory conducts checks on magnet strength and polarity alignment. Improper placement could affect usability or even pose safety concerns, so verification steps are incorporated to confirm that each tile meets required standards.

Quality control in a Magna Tiles Factory extends beyond individual tiles. Batch inspections assess overall color consistency, dimensional accuracy, and packaging integrity. Test assemblies may also be conducted to simulate typical usage scenarios, ensuring that tiles connect as intended without unintended gaps or weak spots. This attention to detail contributes to customer satisfaction and product longevity.

Packaging is another area where a Magna Tiles Factory adds value. Efficient packing systems not only reduce shipping costs but also protect tiles from scratches or deformation. Clear labeling, instructions, and component lists are standard, helping consumers organize sets and understand assembly possibilities. Some factories also offer customized packaging options for promotional purposes or regional markets.

Sustainability is gradually becoming part of factory practices. Some Magna Tiles Factory operations focus on using recyclable plastics, reducing waste during molding, and designing tiles for durability. These measures not only reduce environmental impact but also extend the usable life of the product, offering practical advantages to families and schools.

A Magna Tiles Factory is more than a production site—it is a carefully structured environment where materials, design, and processes converge to create reliable, engaging toys. By understanding the factory's role in material selection, molding precision, assembly, quality checks, and packaging, buyers and educators can make informed decisions about the products they bring into homes and classrooms. This perspective emphasizes consistency, safety, and thoughtful engineering rather than relying on marketing claims.

https://www.magnetictorysfactory.com/product/magnetic-tiles/