A Sand Filled Squishy Toy is a type of stress-relief or sensory toy that has gained attention for its tactile appeal and versatility. Unlike regular squishy toys, these products contain fine sand or similar filling materials, providing a unique texture and resistance that enhances the user experience. Factories that specialize in these toys are responsible for transforming design concepts into safe, functional, and visually appealing products.

In a Sand Filled Squishy Toys factory, production begins with material selection. The outer layer is typically made from soft, flexible materials such as silicone, polyurethane, or TPR (thermoplastic rubber). These materials are chosen for their elasticity, durability, and ability to hold the sand securely. The filling material must be fine, non-toxic, and free from contaminants to ensure both safety and smooth squishiness.

The manufacturing process in a Sand Filled Squishy Toys factory usually includes molding, filling, sealing, and surface finishing. First, the outer shell of the toy is created using molds that determine shape, size, and design details. Once the shells are formed, a measured amount of sand or filler is inserted. Accurate filling is crucial to achieve consistent squishiness across all products. After filling, the toys are sealed using heat, adhesive, or ultrasonic welding methods to prevent leakage and maintain safety standards.

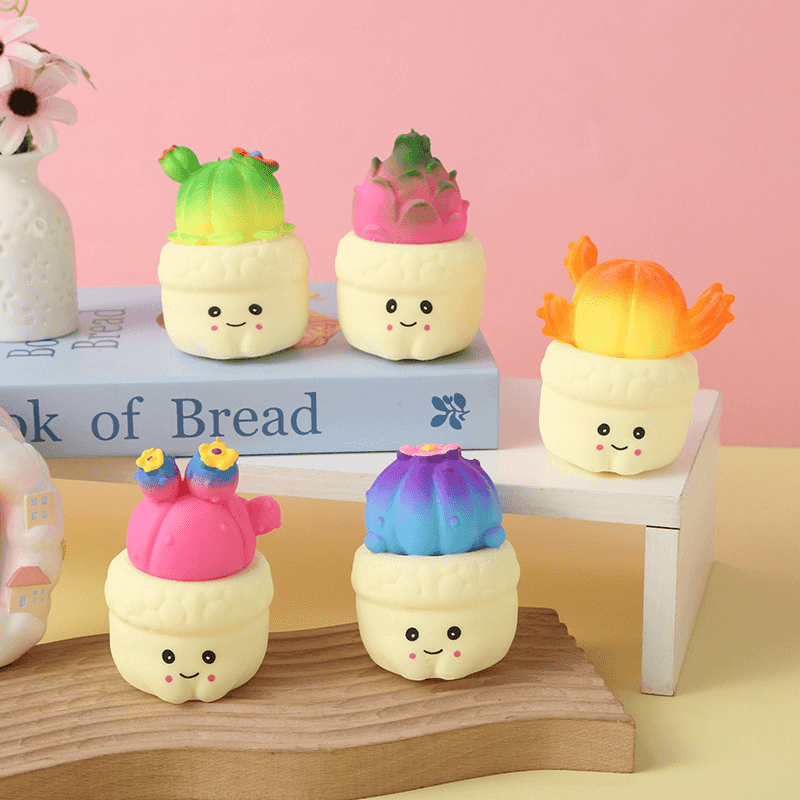

Coloring and decoration are also important stages in a Sand Filled Squishy Toys factory. Factories may use safe dyes or paints to create vibrant patterns or character designs on the toy's surface. Quality control measures ensure that colors remain stable under repeated use and do not transfer to hands or other objects. This attention to detail helps maintain both visual appeal and customer satisfaction.

Quality assurance is a major focus in a Sand Filled Squishy Toys factory. Finished products are typically inspected for shape accuracy, filling consistency, sealing integrity, and surface smoothness. Factories also conduct stress and compression tests to ensure toys withstand repeated squishing without tearing or leaking. Compliance with international toy safety standards is essential, particularly regarding non-toxic materials, choking hazards, and durability.

A Sand Filled Squishy Toys factory often serves a diverse range of customers, including wholesalers, retailers, promotional companies, and brand owners. Demand may vary from simple geometric shapes to character-themed toys, allowing factories to produce a wide variety of designs. Customization options, such as unique colors, packaging, or branded logos, are frequently requested and require flexible production planning.

Packaging and distribution are key aspects in a Sand Filled Squishy Toys factory. Proper packaging protects the toys during transit, prevents dust or moisture intrusion, and maintains their appearance. Factories often prepare boxes or individual pouches with clear labeling and usage instructions. For international shipping, multilingual manuals and compliance with customs regulations are also considered.

A Sand Filled Squishy Toys factory integrates material science, molding expertise, and quality control to produce toys that meet practical and aesthetic requirements. By combining careful material selection, precise filling techniques, and thorough inspection, these factories provide products that offer enjoyable tactile experiences while maintaining safety and durability. The resulting toys appeal to a wide audience, supporting both leisure and promotional markets.