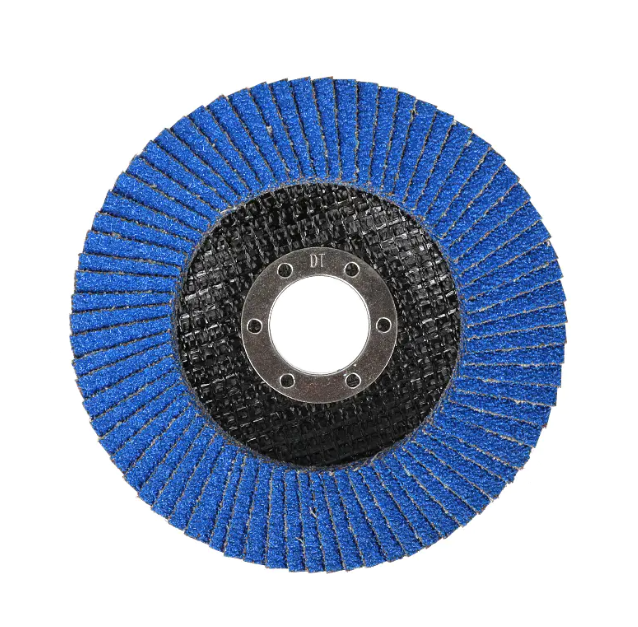

Flap discs are essential abrasive tools used in metalworking, woodworking, and surface finishing applications. They combine multiple overlapping abrasive flaps mounted on a backing plate to provide efficient material removal and smooth finishes. The role of a professional Flap Discs Factory is crucial in producing tools that meet safety standards, maintain consistent quality, and perform reliably across various industries.

A reliable Flap Discs Factory begins with careful material selection. Abrasive grains, such as aluminum oxide, zirconia alumina, or ceramic, are chosen based on intended use, hardness, and durability requirements. The backing plate—often made of fiber, plastic, or metal—needs to provide stability while withstanding the forces generated during grinding. By controlling raw materials, the factory ensures that flap discs deliver predictable performance and longer service life.

Manufacturing precision is a key factor for any Flap Discs Factory. The flaps must be evenly aligned and securely bonded to the backing plate to prevent imbalance, uneven wear, or safety hazards. Automated or semi-automated production lines can improve consistency, especially for large-scale orders. Consistent flap spacing and adhesive application are essential for both durability and smooth operation, reducing vibration and operator fatigue.

Customization and variety are increasingly important in flap disc production. A Flap Discs Factory can offer different grit sizes, diameters, and flap angles to meet the needs of metal fabricators, welders, or woodworking professionals. Specialized products may include reinforced backing plates for high-speed applications or discs designed for polishing, blending, and finishing surfaces. Flexibility in production allows buyers to select tools suited to their specific projects without compromising safety or reliability.

Quality control procedures in a Flap Discs Factory include inspection of abrasive adhesion, flap alignment, and bonding integrity. Discs are often tested for rotational balance, wear rate, and operational safety. These checks ensure that products meet industry standards and perform consistently under expected working conditions. Documentation of these procedures also provides traceability, supporting customer confidence and regulatory compliance.

Logistics and packaging are another important aspect for a Flap Discs Factory. Proper packaging protects discs from moisture, impacts, and deformation during transportation. Clear labeling of grit size, material type, and intended application helps distributors and end users handle the products correctly. For international shipments, secure packaging and proper documentation simplify customs clearance and reduce the risk of product damage.

Customer support and after-sale guidance are additional factors in factory operations. A responsive Flap Discs Factory provides technical advice on storage, tool selection, and safe usage. This support can improve the lifespan of flap discs and ensure consistent results across different working environments. Open communication during order processing also helps buyers plan inventory and production schedules efficiently.

Selecting a Flap Discs Factory that emphasizes material quality, production precision, customization, and consistent quality control ensures that end users receive tools that are safe, durable, and reliable. By focusing on these aspects, the factory supports industrial users in achieving smoother finishes, improved workflow, and predictable results in their daily operations.