For a car mat manufacturer, the primary goal extends far beyond simply covering the floor pan. The product must actively manage the inevitable mess of daily driving—muddy boots, melting snow, spilled coffee, and gritty sand. Two critical design features transform a passive piece of material into an active protective system: integrated drainage channels and perimeter raised edges. The engineering behind these elements is a careful balance of geometry, material science, and an intimate understanding of real-world use.

The Hydrology of the Footwell: Channel Design

Drainage channels are not merely decorative grooves. Their purpose is to capture and direct liquid away from the driver's feet and sensitive vehicle electronics (often located under the front seats) towards lower, contained reservoirs. A skilled car mat manufacturer approaches this like a civil engineer designing a watershed.

Pattern and Depth: Channel patterns are strategically mapped. High-traffic areas, like the heel pad near the accelerator and brake pedals, feature a dense network of interconnected channels. These are often deeper (3-5mm) to handle rapid fluid influx. The channels then converge, guiding liquid toward a central or rear sump area. The angle and depth must ensure liquid flows away from critical control points even when the vehicle is parked on an incline.

Functional Aesthetics: The pattern must also facilitate cleaning. Channels need to be wide enough not to trap pebbles or debris yet deep enough to hold a meaningful volume. Their walls are typically sloped to prevent grime from adhering and to allow for easy pressure washing or wiping. For a car mat manufacturer, designing these channels involves complex mold engineering to ensure the pattern releases cleanly during production, whether for thermoplastic rubber (TPR) injection molding or for cutting dense textile composites.

The Containment Barrier: Raised Edge Engineering

While channels manage liquids, the raised lip or beaded edge is the primary defense against solid debris and the overflow of liquids. This isn't just a slightly rolled edge; it's a substantial, vertical barrier, often 1 to 1.5 inches tall, that fully encircles the mat's perimeter.

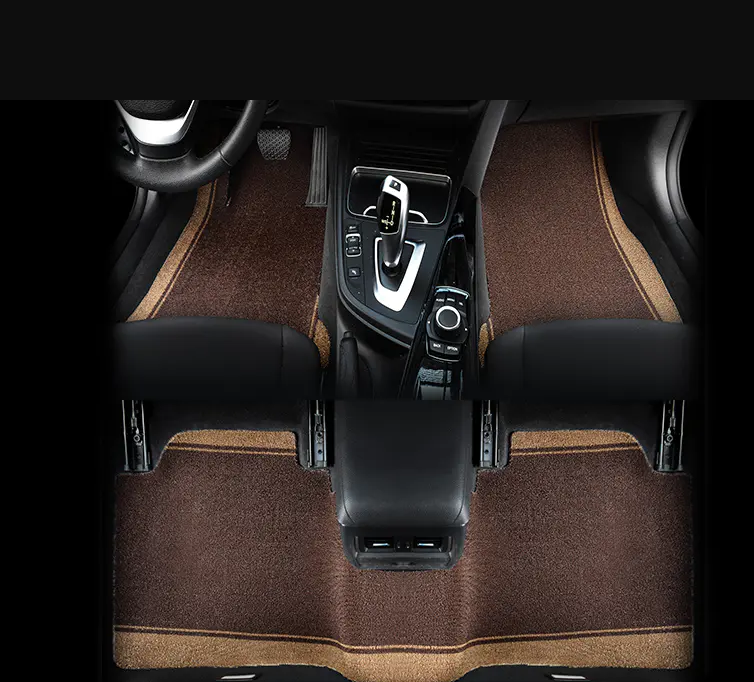

Contour Mapping: The most critical aspect is that this raised edge must follow the exact, often irregular, contour of the vehicle's footwell. A premium car mat manufacturer uses 3D laser scans of factory floor pans to ensure the mat's edge nests perfectly against the plastic trim, sill plates, and center console. This custom contouring eliminates gaps where dirt and water can spill onto the carpet.

Structural Integrity: The raised edge must maintain its shape under pressure. In rubber or TPR mats, this is achieved through specific material durometer (firmness) and ribbed support structures molded into the back of the lip. In fabric mats, the edge is often created by folding and sealing multiple layers of heavy-duty material over a flexible yet resilient core, such as a PVC or rubber bead. This prevents the edge from collapsing when a shoe brushes against it.

The Anti-Slip Connection: The effectiveness of the raised edge is tied directly to the mat's anti-slip backing. If the mat shifts, the seal against the footwell wall breaks. Therefore, the design process is holistic. The car mat manufacturer engineers the backing—whether it's patented cleat systems, nibs, or friction-grip materials—to lock the mat in place, ensuring the raised edge remains in constant contact with the vehicle's interior walls to form a true containment vessel.