First, high-speed steel;

High-speed steel with transfer machine parameters refers to high-alloy tool steel containing more tungsten, chromium, molybdenum, vanadium and other alloying elements. High speed steel can be divided into ordinary high speed steel and high performance high speed steel according to different uses.

General high speed steel has a certain hardness (63-66HRC), wear resistance, high strength toughness. When processing ordinary steel, the cutting speed is 50-60m/min, which is not suitable for high-speed cutting and superhard material processing. W18Cr4V and W6Mo5Cr4V2 are the main brands. The latter is superior to the latter in strength and toughness, but has poor thermal stability.

Second, hard alloy hard alloy;

Powder metallurgy products, made of hard alloy (WC, TiC, TaC, NbC, etc.) with high hardness and high melting point. , Co, Mo, Ni and other elements as binding agents. Its room temperature hardness can reach 78-82HRC, can be used at high temperatures of 800-1000 ° C, and its cutting speed is 4-10 times that of high-speed steel. However, its impact toughness and bending strength are much lower than that of high-speed steel, so it is rarely used as an integral tool. In practice, the carbide cutter block is usually fixed to the cutter body by welding or mechanical clamping.

There are three commonly used cemented carbide;

1, tungsten carbide cobalt (code YG) is composed of tungsten carbide and cobalt.

This kind of cemented carbide has good toughness, but poor hardness and wear resistance, and is suitable for processing brittle materials (such as cast iron, etc.). The more Co in tungsten carbide cobalt, the better the toughness. Commonly used brands are: YG8, YG6, YG3, its tools are roughing, semi-finishing and finishing in turn.

2, tungsten carbide titanium cobalt (code YT) is composed of tungsten carbide, titanium carbide and cobalt.

This kind of cemented carbide has good heat resistance and wear resistance, but poor impact toughness, suitable for cutting strip steel and other plastic materials. Commonly used grades are YT5, YTl5, YT30, etc., where the number represents the content of titanium carbide. The higher the titanium carbide content, the better the wear resistance and the lower the toughness. Tungsten, titanium, cobalt three brands of tools are suitable for rough processing, semi-finishing and finishing.

3, tungsten titanium tantalum (Niobium) carbide (code YW) is composed of tungsten titanium cobalt carbide and a small amount of tantalum carbide (TaC) or niobium carbide (NbC).

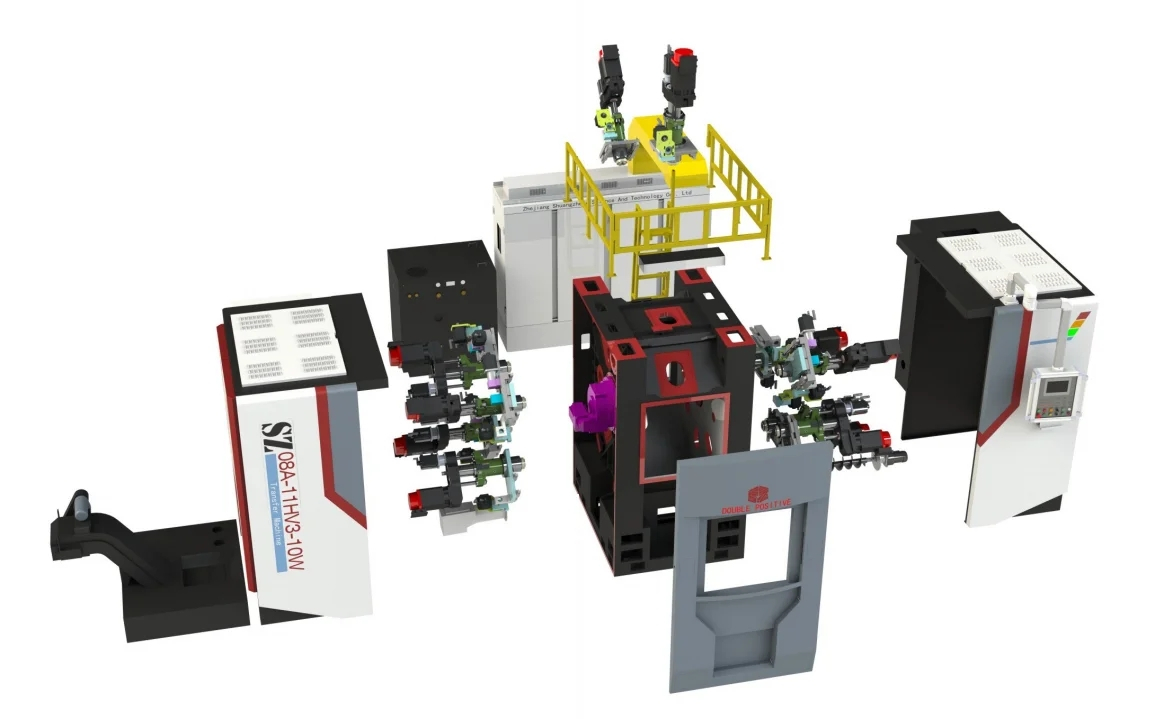

transfer machine https://www.zjshuangzheng.com/Integrated-Transfer-Machine.html