Most punching errors don’t look serious at first. One missed hole. One extra punch. But once parts move downstream, those small issues become real problems. This is where a Counting Punch Press paired with a Foot Operated Electric Punch Press quietly changes outcomes.

Manual counting relies on memory. Memory fails—especially during long shifts or repetitive work. Assemblers notice gaps later. Supervisors investigate earlier steps. Production slows.

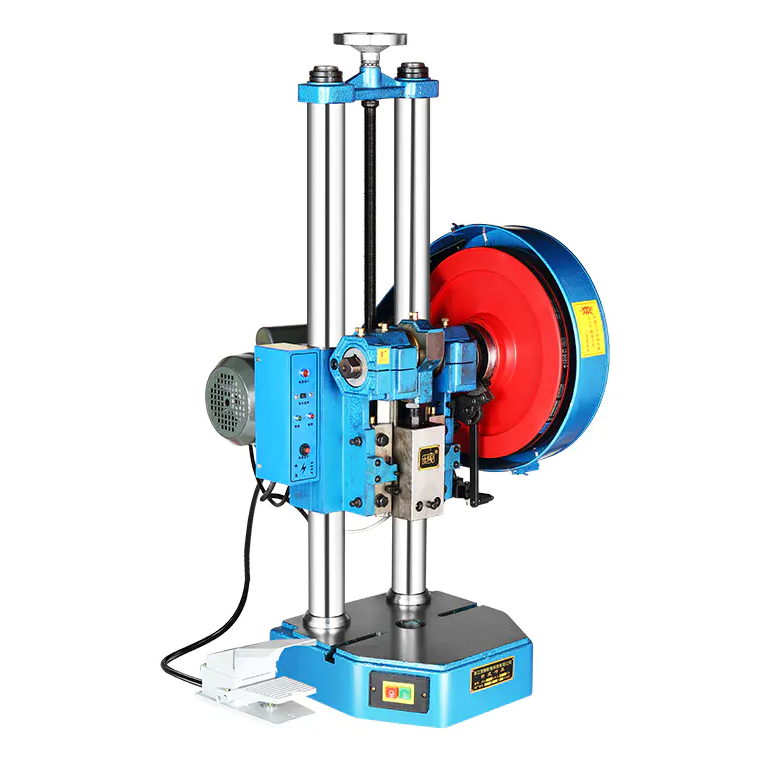

A Counting Punch Press prevents these issues upstream. Operators know exactly where they are in the process. No guessing. No backtracking.

The foot-operated design keeps movements natural. Operators stay focused on alignment, not counting.

Edge scenarios matter most—complex layouts, mixed orders, multitasking operators. Instead of multiplying errors, the system stabilizes the workflow.

Less rework means fewer tense conversations between departments. Quality improves without extra inspections.

Accuracy doesn’t have to be stressful. It can be built into the process.