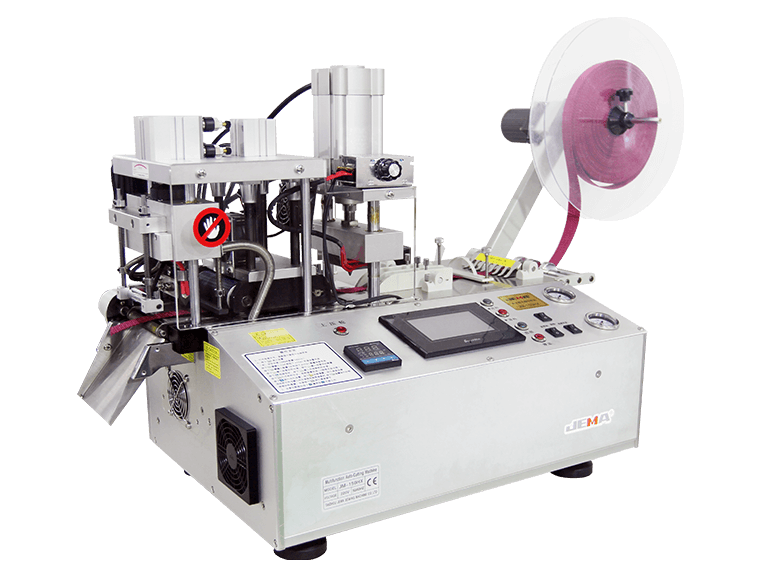

Introduction to Elastic Tape Cutting Machines

An Elastic Tape Cutting Machine is designed to automate the process of cutting elastic bands to precise lengths for garments, medical supplies, and other textile applications. These machines improve production efficiency, reduce material waste, and provide consistent cuts. In comparison, semi-automatic elastic tape cutting machines require partial human intervention, which affects workflow and overall output. Understanding the differences between fully automatic and semi-automatic models is essential for manufacturers deciding which type best suits their production needs.

Automation Level and Operation

The primary difference between a full Elastic Tape Cutting Machine and a semi-automatic model lies in the level of automation. Fully automatic machines can feed, cut, and stack elastic tape continuously with minimal human involvement. Operators mainly monitor the machine, adjust settings, and manage the output. In contrast, semi-automatic machines typically require an operator to manually feed the tape into the cutting mechanism and sometimes manually remove the cut pieces. This increased human involvement can slow down production and introduce variability in cutting precision.

Production Efficiency

Production efficiency is another key distinction. Fully automatic machines are designed for high-volume production, capable of cutting large quantities of elastic tape in a short time while maintaining consistent length and quality. Semi-automatic machines, due to manual intervention, generally have a lower throughput and are more suited for small to medium-scale production. For businesses aiming to scale up production, investing in a fully automatic machine can result in significant time and labor savings.

Precision and Consistency

A fully automatic elastic tape cutting machine often provides higher cutting accuracy and consistency than semi-automatic models. Automatic machines utilize programmable settings and precision blades to ensure uniform lengths and smooth edges, even with varying tape thicknesses. Semi-automatic machines rely more heavily on the operator’s skill, which can introduce slight variations in length or quality, especially during long production runs.

Maintenance and Cost Considerations

While fully automatic machines tend to be more expensive upfront due to advanced features, they often reduce labor costs over time and minimize material waste. Semi-automatic machines are more affordable initially but may require more personnel to operate and supervise. Both types require regular maintenance, such as blade sharpening and lubrication, but fully automatic machines often have more sophisticated systems that demand careful monitoring to maintain peak performance.

Choosing between an Elastic Tape Cutting Machine and a semi-automatic model depends on production volume, budget, and desired efficiency. Fully automatic machines excel in high-volume, precision-driven environments, providing consistent cuts with minimal human intervention. Semi-automatic machines offer flexibility and lower upfront costs, making them suitable for smaller operations or businesses with variable production demands. Understanding these differences ensures manufacturers select the right solution for their specific production needs.