An ANSI Butterfly Valve is a type of quarter-turn valve widely used in industrial piping systems to control the flow of liquids, gases, and slurries. Designed according to American National Standards Institute (ANSI) specifications, this valve provides consistent performance, reliable sealing, and ease of operation across a range of applications. Manufacturers and facility operators rely on ANSI Butterfly Valves for their durability, versatility, and relatively simple design, which allows for cost-effective installation and maintenance.

The primary function of an ANSI Butterfly Valve is to regulate flow by rotating a disc within the valve body. When the disc is turned 90 degrees, it either allows full flow or completely blocks it. Partial rotation can also control flow rates, making the ANSI Butterfly Valve suitable for throttling operations. Its compact design and lightweight structure compared to other valve types, such as gate or globe valves, make it a preferred choice for large-diameter pipelines where weight and space are considerations.

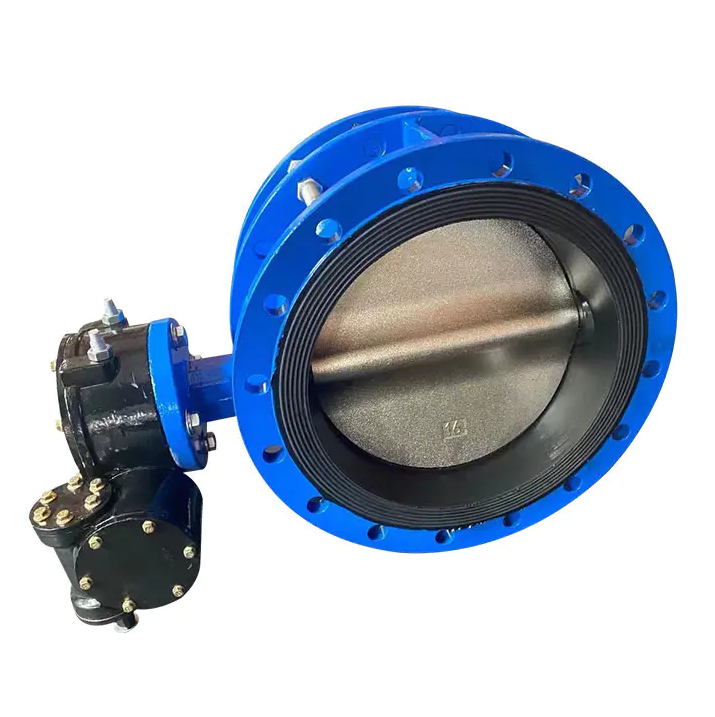

Durability and material selection are key features of ANSI Butterfly Valves. Valve bodies are typically constructed from cast iron, ductile iron, stainless steel, or carbon steel, depending on the application and fluid characteristics. The disc and seat materials are selected to withstand pressure, temperature, and chemical exposure, ensuring reliable operation in both corrosive and abrasive environments. Manufacturers often offer options such as resilient-seated or metal-seated designs, allowing the valve to meet specific industrial requirements.

ANSI Butterfly Valves are valued for their ease of operation. The quarter-turn mechanism requires minimal effort, and these valves can be operated manually with a lever or wheel, or automated using electric or pneumatic actuators. This versatility allows the valve to be integrated into automated control systems, supporting remote operation and process automation. Additionally, ANSI Butterfly Valves have a relatively low maintenance requirement due to their simple construction and fewer moving parts.

Installation and compatibility are also important considerations. ANSI Butterfly Valves conform to standardized dimensions and flange patterns, which ensures they can be integrated into existing piping systems without extensive modifications. This standardization simplifies replacement, retrofitting, and expansion projects. The lightweight design of the valve further reduces installation labor and handling challenges, particularly for larger pipeline diameters.

Performance under pressure and temperature conditions is a critical factor for ANSI Butterfly Valves. They are available in different pressure classes, such as ANSI Class 150, 300, or 600, allowing selection according to system requirements. Proper valve sizing, disc selection, and seat type ensure that the valve can operate efficiently while minimizing leakage and wear. Regular inspection and periodic maintenance, such as checking seat integrity and actuator function, help maintain performance over the valve's service life.

ANSI Butterfly Valves are used in diverse industries, including water treatment, chemical processing, oil and gas, HVAC, and food and beverage production. Their compact design, reliability, and ability to handle various media make them suitable for both on/off control and flow regulation applications. By providing an effective solution for controlling fluid flow, ANSI Butterfly Valves contribute to operational efficiency and process safety.

In conclusion, an ANSI Butterfly Valve is a versatile and reliable component for industrial piping systems. Its simple design, durable construction, and ease of operation make it suitable for a wide range of applications and industries. By selecting the appropriate material, pressure class, and seat type, users can ensure that an ANSI Butterfly Valve provides consistent performance, efficient flow control, and long-term operational reliability in demanding environments.