The Cold Milling Machine Market has emerged as a crucial segment of the global construction and infrastructure industry, reflecting the growing demand for efficient, cost-effective, and environmentally sustainable road construction solutions. Cold milling machines, often referred to as cold planers, are heavy equipment used for the precise removal of asphalt and concrete surfaces. Unlike conventional hot milling, cold milling preserves the material integrity by avoiding overheating, enabling recycling, and reducing waste. With global infrastructure spending on the rise, technological advancements, and sustainability becoming central to construction practices, the cold milling machine market is positioned for substantial growth between 2024 and 2034.

Market Size and Forecast

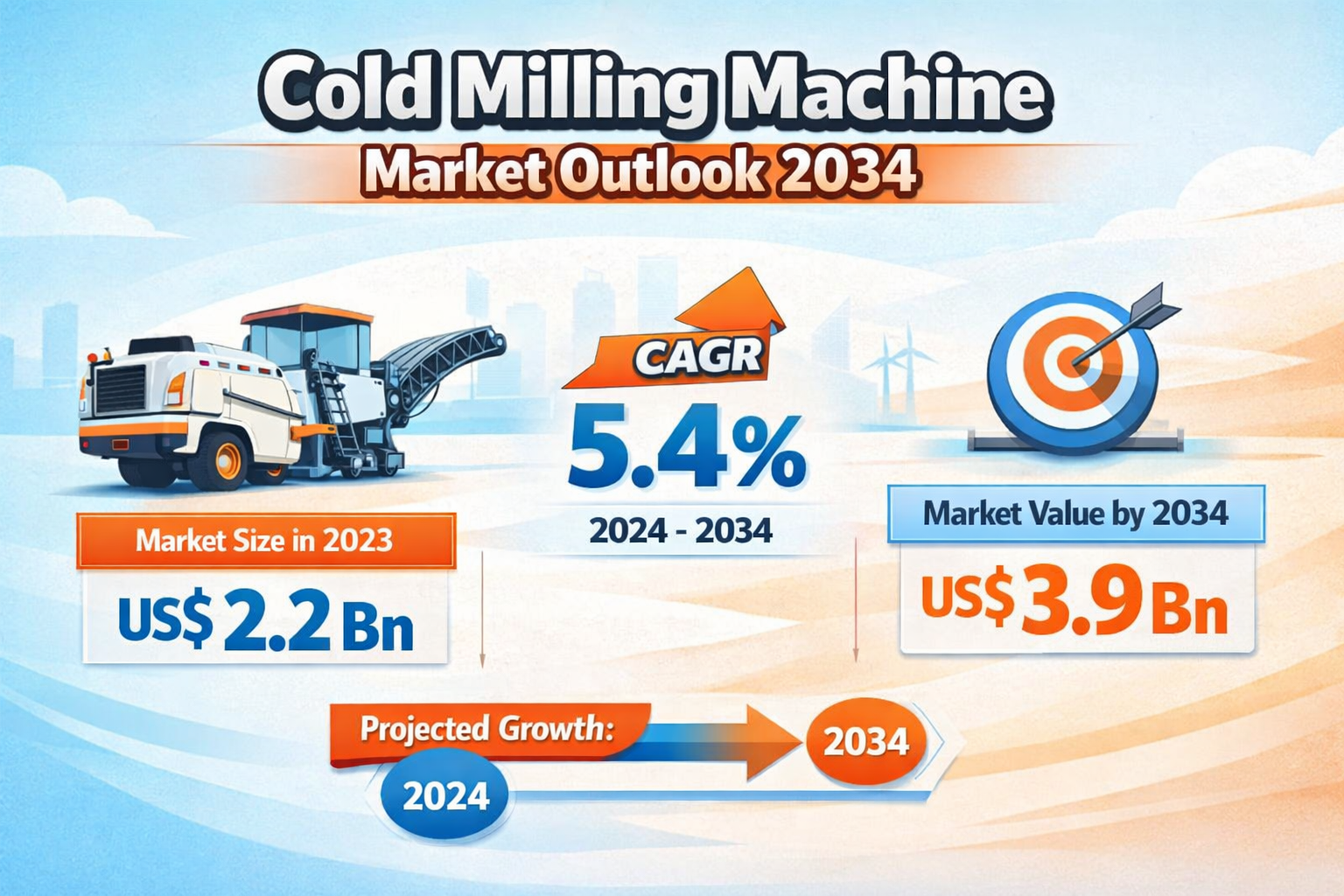

As of 2023, the global cold milling machine market was valued at US$ 2.2 billion . Forecasts indicate that the market will grow at a CAGR of 5.4% , reaching approximately US$ 3.9 billion by 2034. This steady expansion is fueled by demand from both developed and emerging economies, where modern road construction and rehabilitation projects are critical for economic growth and transportation efficiency.

Cold milling machines offer precision, reliability, and eco-friendliness, which aligns with the increasing preference for sustainable construction practices. They are particularly favored for urban road maintenance, highway reconstruction, and airport runway resurfacing projects.

Driving Factors

1. Expanding Infrastructure and Road Development Initiatives

Infrastructure development is a primary factor propelling cold milling machine adoption. Governments and private sector investments are continuously expanding road networks, highways, and urban connectivity projects:

-

India : Through the National Infrastructure Pipeline (NIP) , India plans to invest over US$ 1.4 trillion in infrastructure by 2025, creating opportunities for cold milling technology adoption.

-

United States : The Infrastructure Investment and Jobs Act allocates US$ 1.2 trillion to modernize roads, highways, and transportation networks, increasing the need for precision equipment.

-

Global Outlook : As per the Global Infrastructure Hub, worldwide infrastructure investment is projected to reach US$ 94 trillion by 2040 , with road construction as a major segment.

In addition to new projects, aging infrastructure in many developed regions necessitates constant maintenance and rehabilitation. The American Society of Civil Engineers (ASCE) has rated the US infrastructure as a C-, highlighting the urgency for road improvement and resurfacing activities. Cold milling machines are key tools in these efforts, ensuring efficiency and cost-effectiveness.

2. Technological Innovation Driving Adoption

Technological progress in cold milling machines has significantly enhanced their efficiency, precision, and environmental performance:

-

Automation: Wirtgen Group and other manufacturers have integrated automated systems that reduce operator fatigue while ensuring consistent milling depth and superior surface quality.

-

GPS and Digital Integration: Volvo Construction Equipment offers GPS-enabled cold milling machines, improving accuracy in road rehabilitation and reducing material waste. Caterpillar’s VisionLink® Productivity system provides real-time data analytics to track machine performance, minimize downtime, and optimize productivity.

-

Fuel Efficiency and Emission Compliance: Modern engines are designed to meet stringent emission standards (Tier 4), appealing to environmentally-conscious operators and reducing operational costs.

These innovations allow construction firms to achieve higher precision, improved project timelines, and greater sustainability, making technologically advanced cold milling machines highly desirable in global markets.

3. Sustainability and Recycling Initiatives

Environmental sustainability is reshaping the construction equipment market, with cold milling machines offering significant advantages:

-

Recycling Capabilities: Cold milling enables on-site recycling of asphalt and concrete, reducing the need for virgin materials and minimizing construction waste. Recycled materials can be directly reintegrated into new pavements or asphalt mixes.

-

Compliance with Environmental Regulations: Governments worldwide, including those in Europe under the Green Deal, promote eco-friendly construction practices that reduce carbon emissions and material consumption.

-

Cost Reduction: Recycling milled materials lowers costs associated with raw material acquisition, transportation, and waste disposal, providing economic as well as environmental benefits.

These factors position cold milling technology as a central component of sustainable construction practices, aligning with circular economy principles and climate-conscious policies.

Market Segmentation

The cold milling machine market is segmented by product type, size, engine power, and application to cater to diverse construction requirements.

By Product Type

-

Drum-Type Cold Milling Machine: High-precision machines for major highways and extensive road networks.

-

Crawler-Type Cold Milling Machine: Optimized for stability and maneuverability on uneven surfaces.

-

Wheel-Type Cold Milling Machine: Fast-moving machines suitable for specialized resurfacing tasks.

By Size

-

Small: Ideal for minor road repairs and urban projects.

-

Compact/Medium: Suited for city streets and regional roads.

-

Large: Designed for highways, airports, and large-scale infrastructure projects.

By Engine Power

-

Less than 155 kW

-

155–300 kW

-

Above 300 kW

By Application

-

Asphalt Pavement

-

Concrete Pavement

-

Others: including removal of pavement markings

These segments enable manufacturers to offer machines that precisely match project requirements, ensuring performance efficiency and cost-effectiveness.

Regional Insights

Asia Pacific: The Leading Region

Asia Pacific dominates the cold milling machine market, primarily due to rapid urbanization, government investments, and large-scale infrastructure projects.

-

China: The Belt and Road Initiative (BRI) has driven thousands of road projects, increasing the demand for cold milling technology.

-

India: National and state-level projects under the NIP aim to expand road connectivity and modernize transportation networks.

-

Infrastructure Funding: According to the Asian Development Bank (ADB), annual infrastructure investment in developing Asia is estimated at US$ 1.7 trillion, with significant allocations for roads.

North America and Europe

Growth in these regions is steady due to infrastructure maintenance and modernization initiatives, stringent environmental regulations, and the adoption of advanced construction technologies.

Middle East, Africa, and South America

These regions represent emerging markets, driven by urbanization, industrial expansion, and government-backed road projects. Demand for cold milling machines is increasing as countries strive to modernize and expand their transport networks.

Key Players and Competitive Landscape

The cold milling machine market is competitive, with key manufacturers focusing on technological innovation, sustainability, and geographic expansion. Notable companies include:

-

Astec Industries, Inc. (Roadtec)

-

Bomag GmbH

-

Caterpillar Inc.

-

CMI Roadbuilding Limited

-

Fayat Group

-

Jiangsu Huatong Power Heavy Industry Co Ltd.

-

Liugong Machinery Co Ltd.

-

Sakai Heavy Industries, Ltd.

-

SANY GROUP

-

WIRTGEN

Recent Developments:

-

Sany Group (2024): Introduced truck-mounted concrete pumps in Athens and Thessaloniki, diversifying product offerings.

-

Caterpillar (2024): Launched VisionLink® Productivity for PM600 and PM800 series, providing digital monitoring and performance optimization for cold planers.

The market competition is increasingly influenced by technological innovation, sustainability compliance, and the ability to deliver high-efficiency machines for diverse projects.

Future Opportunities and Market Outlook

The cold milling machine market offers promising growth opportunities in the coming decade:

-

Infrastructure Expansion: Ongoing road construction and highway modernization will continue to drive demand.

-

Technology Integration : AI, GPS, and IoT-enabled machines will enhance precision, efficiency, and safety.

-

Sustainability Practices : Emphasis on recycling and eco-friendly construction will encourage adoption of cold milling technology.

-

Emerging Economies : Rapid urbanization in Asia, South America, and Africa will create new market opportunities.

-

Public-Private Partnerships (PPPs) : Collaborative infrastructure projects will support leasing, rentals, and new product deployment.

Despite challenges such as high capital investment and the need for skilled operators, cold milling machines remain indispensable for modern road construction and rehabilitation, offering operational efficiency, reduced material waste, and environmental benefits.

Analyst's Perspective

Industry analysts suggest that the cold milling machine market will witness consistent growth as global infrastructure projects expand, technological innovations improve operational efficiency, and sustainability requirements become central to construction practices. Governments and contractors increasingly prefer advanced, eco-friendly cold milling machines for road rehabilitation, resurfacing, and large-scale infrastructure projects.

Conclusion

The Cold Milling Machine Market is poised for robust growth, driven by global infrastructure spending, technological advancements, and sustainability-focused construction practices. With ongoing innovations and adoption in emerging economies, the market is set to expand steadily throughout 2024-2034.