Innovations in additive manufacturing, automation, and composite materials are reshaping the Aerospace Parts Manufacturing Market , enabling faster production times and enhanced performance. These technological trends are helping manufacturers meet evolving industry requirements and reduce production costs.

Key Growth Drivers

Rising Air Traffic and Fleet Expansion is one of the most significant forces propelling market growth. As global air travel rebounds and continues to grow, airlines and governments are investing heavily in new aircraft. This expansion generates demand not only for new parts — engines, avionics, landing gear, and structural components — but also for maintenance, repair, and overhaul (MRO) services for existing fleets. The MRO sector alone represents a substantial and recurring demand stream for high-quality aerospace components.

Get Sample Brochure at https://www.theinsightpartners.com/sample/TIPRE00016915

Defense and Space Exploration Investments are also fueling momentum. Governments worldwide are channeling substantial budgets into military aviation, unmanned aerial vehicles (UAVs), and next-generation fighter jets. Simultaneously, the rapid commercialization of space — driven by satellite constellations, space tourism, and deep-space missions — is creating fresh demand for high-performance components built to exacting standards.

Demand for Electric Aircraft Components represents an emerging and transformative driver. As the aerospace sector pivots toward sustainability, manufacturers are investing in technologies compatible with hybrid and electric propulsion systems, driving the need for specialized, lightweight, and energy-efficient parts.

Future Trends Shaping the Market

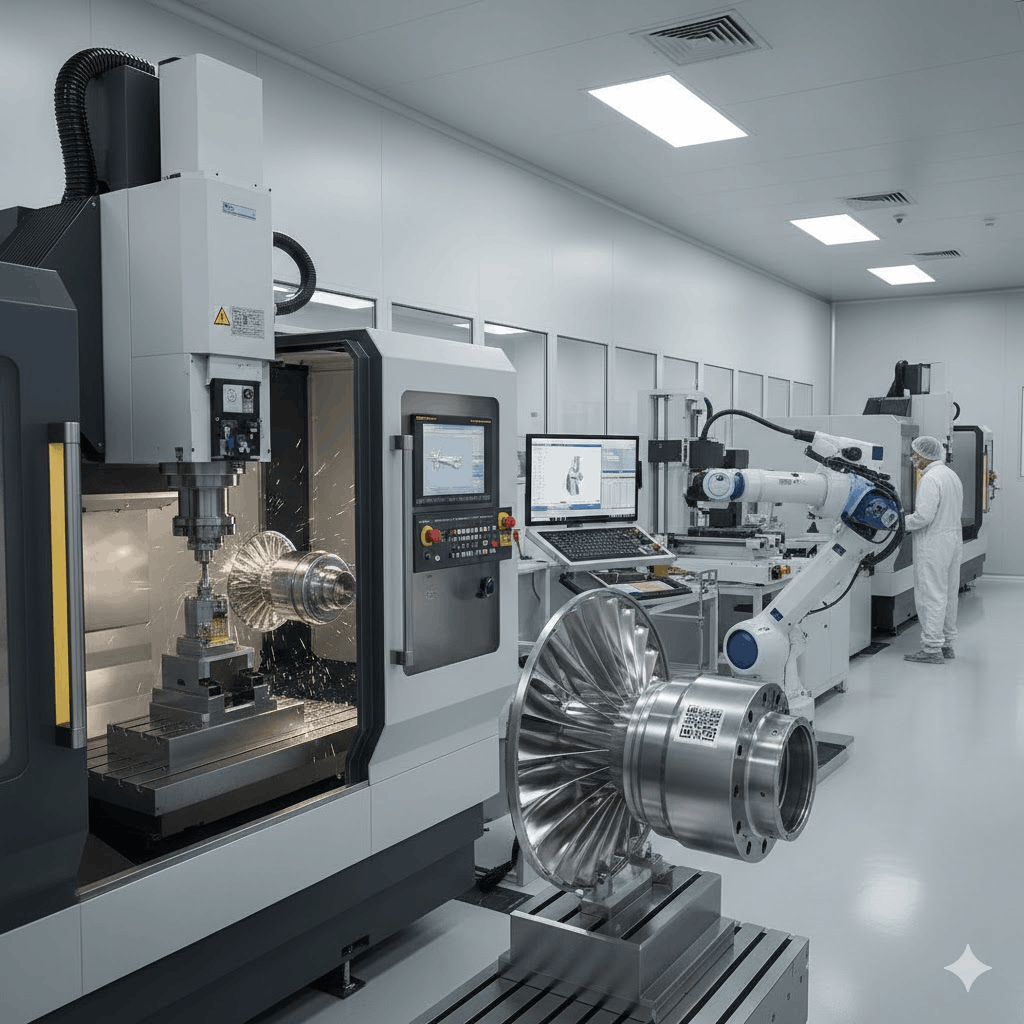

The report highlights several key trends expected to define the market's evolution through 2034. Automation and digitalization of manufacturing processes are gaining pace, with manufacturers incorporating smart factory technologies to enhance precision, reduce waste, and improve throughput. Meanwhile, modular and standardized component design is becoming increasingly prevalent, enabling manufacturers to streamline production across multiple platforms, reduce costs, and simplify maintenance cycles.

Additive manufacturing, or 3D printing, is another transformative trend. This technology allows manufacturers to produce complex, lightweight parts with minimal material waste, accelerating prototyping and lowering production costs — particularly for low-volume, high-precision components used in advanced aerospace applications.

Green manufacturing is also rising in priority. Driven by industry-wide sustainability mandates, manufacturers are reducing energy consumption, embracing eco-friendly materials, and engineering components that contribute to lower aircraft emissions and improved fuel efficiency.

Place Order for the Copy of this Report at https://www.theinsightpartners.com/buy/TIPRE00016915

Competitive Landscape

The market features a mix of established global players and specialized manufacturers. Key companies profiled include Rolls-Royce PLC, Safran Group, Eaton Corporation Plc, Woodward Inc., JAMCO Corporation, Intrex Aerospace, Aequs, and Engineered Propulsion Systems, among others. These players are investing in R&D, strategic partnerships, and capacity expansion to capitalize on the growing demand.

Conclusion

The aerospace parts manufacturing market stands at a pivotal juncture, driven by expanding air travel, defense modernization, space exploration, and the push toward sustainable aviation. With a projected CAGR of 7.9% through 2034, the sector offers compelling opportunities for manufacturers, investors, and technology providers alike. The Insight Partners' report serves as a vital strategic tool for stakeholders looking to navigate this dynamic and rapidly evolving market landscape.

Also Available in : Korean German Japanese French Chinese Italian Spanish