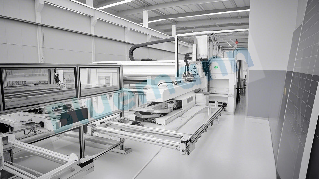

The double-glass fusion machine stands as a cornerstone in the realm of photovoltaic (PV) module production. As the name suggests, this equipment specializes in the manufacturing of double-glass PV modules—a structure comprising two layers of glass sandwiching the photovoltaic cells and packaging materials. This innovative technology not only enhances the durability and reliability of PV modules but also ensures resilience against harsh weather conditions.

Core Features and Functionalities

Precision Laminating Technology

The heart of the double-glass laminating machine lies in its ability to accurately fuse the upper glass, photovoltaic cell layer (typically EVA/POE film), and the lower glass through advanced high-temperature and high-pressure technology. This process results in a seamlessly bonded double-glass component, characterized by exceptional structural integrity and long-term performance.

Automated Precision Alignment

One of the machine's most compelling selling points is its automated precision alignment system. Before the lamination process begins, the upper glass hovers just above the lower glass, ensuring perfect alignment. Both glasses are simultaneously straightened to maintain uniformity during the closing phase. This meticulous attention to detail minimizes defects and enhances the aesthetic appeal of the final product.

The Advantages of Intelligent Double Glass Laminating Machines

High Reliability and Weather Resistance

Double-glass PV modules produced by these machines exhibit superior reliability and weather resistance. The fusion of two glass layers creates a robust barrier against environmental stressors such as wind, rain, snow, and extreme temperatures. This resilience ensures consistent energy production and extends the lifespan of the PV modules, making them a cost-effective investment for both residential and commercial applications.

Enhanced Efficiency and Production Capacity

The intelligent double glass laminating machine is designed for maximum efficiency and productivity. Automated processes streamline the manufacturing workflow, reducing human error and minimizing downtime. With the ability to handle multiple modules simultaneously, these machines significantly increase production capacity, enabling manufacturers to meet growing market demands more effectively.

Cost-Effective and Sustainable Manufacturing

By leveraging automated and precision-controlled processes, the double-glass laminating machine optimizes material usage, reducing waste and lowering production costs. Furthermore, the use of double-glass structures in PV modules enhances energy efficiency and reduces the carbon footprint associated with electricity generation. This contributes to a more sustainable manufacturing process and aligns with the global shift towards renewable energy sources.

Applications and Market Potential

Diverse Applications

The versatility of double-glass PV modules makes them suitable for a wide range of applications. From residential rooftops to large-scale commercial installations, these modules offer unparalleled performance and durability. Their ability to withstand harsh conditions makes them ideal for regions with extreme climates, further broadening their market potential.

Growing Market Demand

As the global transition to renewable energy accelerates, the demand for efficient and reliable PV modules is expected to surge. Intelligent double glass laminating machines are poised to capitalize on this trend, providing manufacturers with the tools necessary to produce high-quality modules in large quantities. This growing market demand presents significant opportunities for both equipment manufacturers and PV module producers.

Conclusion

The intelligent double glass laminating machine represents the future of automated production in the renewable energy sector. By combining precision technology, automated processes, and sustainable manufacturing practices, these machines are setting new standards for reliability, efficiency, and productivity. As the market for double-glass PV modules continues to expand, manufacturers who adopt this advanced equipment will be well-positioned to capitalize on the growing demand for renewable energy solutions. The double-glass fusion machine is not just a tool; it is a catalyst for a cleaner, more sustainable future.