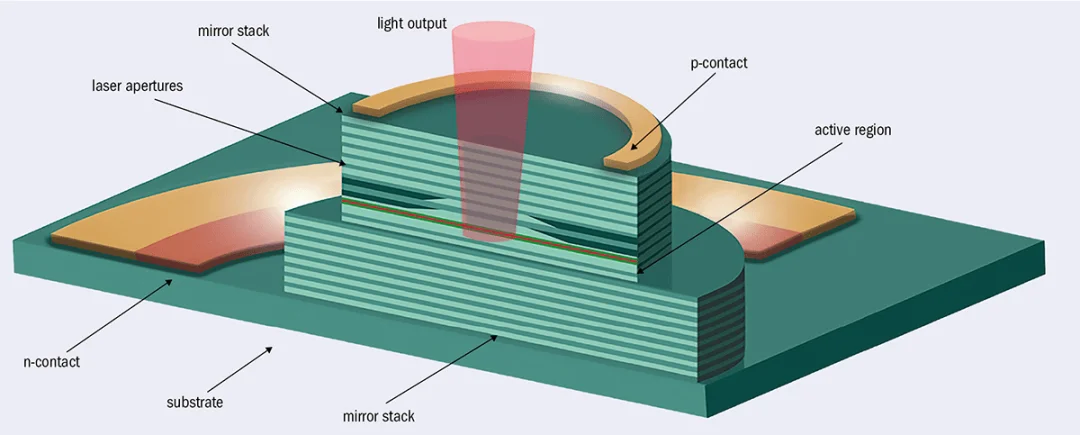

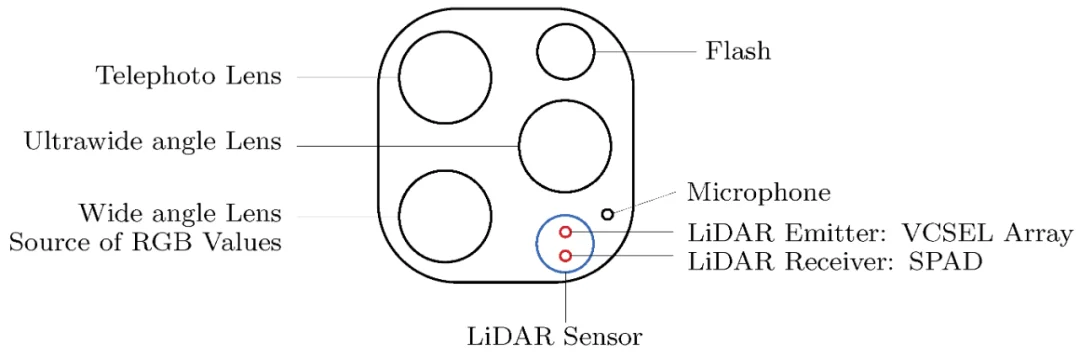

A VCSEL (Vertical-Cavity Surface-Emitting Laser) is a type of semiconductor laser. Compared to traditional edge-emitting lasers ( EELs ), VCSELs offer significant advantages: excellent beam quality, low threshold current, and ease of two-dimensional integration. They are widely used in optical communications, laser displays, optical storage, 3D sensing, automotive radar, atomic clocks, and air and water quality monitoring. The iPhone 15 uses VCSELs for Face ID facial recognition.

In addition, VCSEL's solid-state lidar has the characteristics of high reliability, stability and miniaturization, and has begun to be used in automotive lidar.

According to Yole , the global VCSEL market is expected to grow from US$1.2 billion in 2021 to US$2.4 billion in 2026, with a compound annual growth rate of 13.6%.

High-power VCSELs have become a significant research area, with high-temperature stable operation and high reliability attracting increasing attention in recent years. DPC (Direct Plating Copper) ceramic substrates are widely used in VCSELs, primarily due to their excellent thermal conductivity, electrical properties, and mechanical strength. Their application in VCSEL lasers is primarily reflected in the following aspects:

▌ Good heat dissipation

The low chip conversion efficiency of VCSEL lasers leads to serious heat dissipation issues. DPC ceramic substrates are vertically interconnected to form independent internal conductive channels. The ceramic itself is both an insulator and a heat dissipator, achieving thermal and electrical separation, effectively solving the heat dissipation problem of VCSEL lasers.

High reliability

VCSEL lasers have high power densities, necessitating consideration of stress caused by thermal expansion mismatches between the GaAs / GaN chip and the substrate. DPC ceramic substrates, with a highly matched thermal expansion coefficient for VCSELs, can reduce this stress, thereby improving laser reliability. Furthermore, DPC ceramic substrates enable the metal frame and ceramic substrate to be integrally molded, creating a tight bond. This avoids the need for additional bonding steps and alignment precision during later assembly, as well as reliability issues caused by glue aging.

Vertical Interconnection

The vertical structure of a VCSEL laser requires the lens to be mounted above the chip, meaning the substrate must be constructed as a three-dimensional cavity. DPC ceramic substrates offer unique technical advantages such as high resolution, high flatness, and highly reliable vertical interconnects, making them ideal for vertical eutectic bonding. This eliminates the drawbacks of thick-film substrates like LTCC and HTCC, such as low dimensional accuracy and rough circuitry.

▌ Good packaging adaptability

DPC ceramic substrates nearly meet the packaging requirements of VCSEL lasers. They utilize surface deposition processes such as evaporation and magnetron sputtering to metallize the substrate surface. Circuitry is then fabricated using image transfer on the thin-film metallized ceramic substrate. Electroplating and via sealing techniques are then employed to create a high-density, double-sided ceramic circuit board. DPC ceramic substrates offer numerous advantages, including high thermal conductivity, high insulation, high circuit accuracy, high surface flatness, and a thermal expansion coefficient that matches the chip. These advantages have rapidly established them as a key component in high-power VCSEL component packaging .

https://www.y-crystaled.net/a-match-made-in-heaven-vcsel-packaged-on-ceramic-substrates.html