Introduction to Surface Protection on Permanent Magnetic Chucks

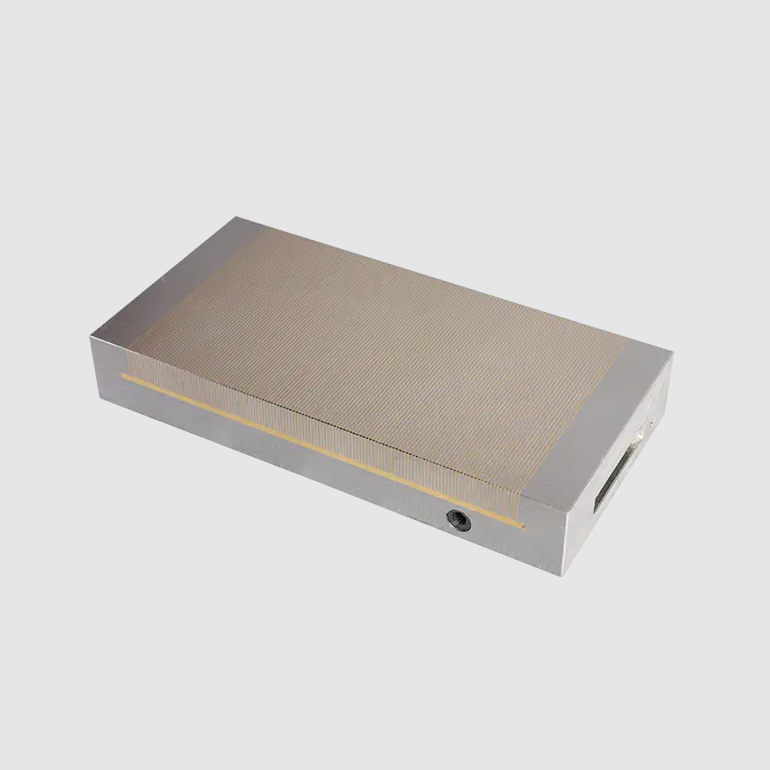

Permanent Magnetic Chucks are widely used in machining and metalworking to securely hold ferromagnetic workpieces during operations like milling, grinding, and drilling. While they provide reliable magnetic holding without electricity, direct contact between the chuck and the workpiece can sometimes cause surface scratches or abrasions. These scratches may affect the precision, appearance, and functionality of the workpiece. Therefore, implementing effective strategies to protect the surface is essential for maintaining quality and prolonging the life of both the workpiece and the Permanent Magnetic Chuck itself.

Factors Contributing to Surface Scratches

Surface scratches on workpieces typically occur due to several factors, including direct metal-to-metal contact, dirt or debris trapped between the chuck and the workpiece, and repeated sliding or repositioning. Hard or rough workpiece materials can exacerbate the problem by increasing friction during placement or removal. Even minor particles of dust, rust, or scale can act as abrasives, creating fine scratches across the surface. Recognizing these contributing factors allows operators to implement appropriate protective measures before beginning machining tasks.

Protective Methods and Techniques

One of the simplest and most effective methods to prevent scratches is the use of thin protective layers, such as soft iron sheets, plastic films, or rubber mats, between the workpiece and the Permanent Magnetic Chuck. These layers provide a buffer that absorbs minor imperfections and distributes pressure evenly, reducing direct abrasion. Operators can also employ thin ferromagnetic backing plates to enhance magnetic contact while simultaneously protecting delicate workpiece surfaces. Careful placement and alignment of the workpiece help minimize sliding, further reducing the risk of scratches.

Importance of Cleanliness and Surface Preparation

Maintaining cleanliness is critical for preventing surface damage. Both the chuck surface and the workpiece should be thoroughly cleaned before contact. Removal of metal shavings, dust, oil, or rust ensures a smooth interface, allowing the magnetic force to hold the workpiece securely without unwanted abrasions. Regular cleaning of the Permanent Magnetic Chuck and inspection for surface imperfections helps maintain consistent protection during operations.

Proper Handling and Operational Practices

Operators should adopt careful handling techniques to avoid dragging or sliding workpieces across the magnetic chuck surface. Lifting and gently placing the workpiece reduces friction and the risk of scratches. When working with multiple pieces or irregularly shaped components, using soft padding or temporary clamps can further prevent unwanted contact. Additionally, periodic inspection and maintenance of the chuck’s surface ensure it remains free of dents or sharp edges that could damage workpieces.

Conclusion

Preventing surface scratches when using a Permanent Magnetic Chuck requires a combination of protective materials, careful handling, and strict cleanliness practices. Using soft interlayers, backing plates, and maintaining a debris-free environment minimizes direct contact and friction that could harm the workpiece. Proper operational techniques, combined with regular maintenance, not only protect the metal surfaces but also prolong the functional life of the chuck. By implementing these strategies, operators can ensure high-quality results while fully leveraging the efficiency and reliability of Permanent Magnetic Chucks in industrial applications.