Railway infrastructure is built on thousands of interconnected components that must remain stable under heavy loads, changing climates, and continuous vibration. Among these components, the sleeper fastener—the system that secures rails to sleepers—plays one of the most decisive roles in determining track integrity, operational safety, and long-term maintenance efficiency.

In global railway engineering, particularly across heavy-haul, high-speed, and urban transit lines, the reliability of sleeper fasteners is now more critical than ever. As operators seek safe, durable, and cost-effective fastening systems, manufacturers such as HuiBo Railway continue to push the boundaries of precision engineering and material performance to meet these evolving demands.

What Exactly Is a Sleeper Fastener

A sleeper fastener (often referred to as a rail fastening system) is a mechanical assembly that connects steel rails to concrete, wooden, or composite sleepers. Its core functions include:

Maintaining accurate track gauge under dynamic loads

Damping vibration and reducing noise

Improving track stability during acceleration, braking, and temperature-induced expansion

Distributing loads evenly into the sleeper

Preventing rail movement, including longitudinal creep and lateral displacement

Sleeper fasteners are engineered to meet the specific demands of railway systems—whether heavy-haul freight, high-speed passenger routes, or urban transit.

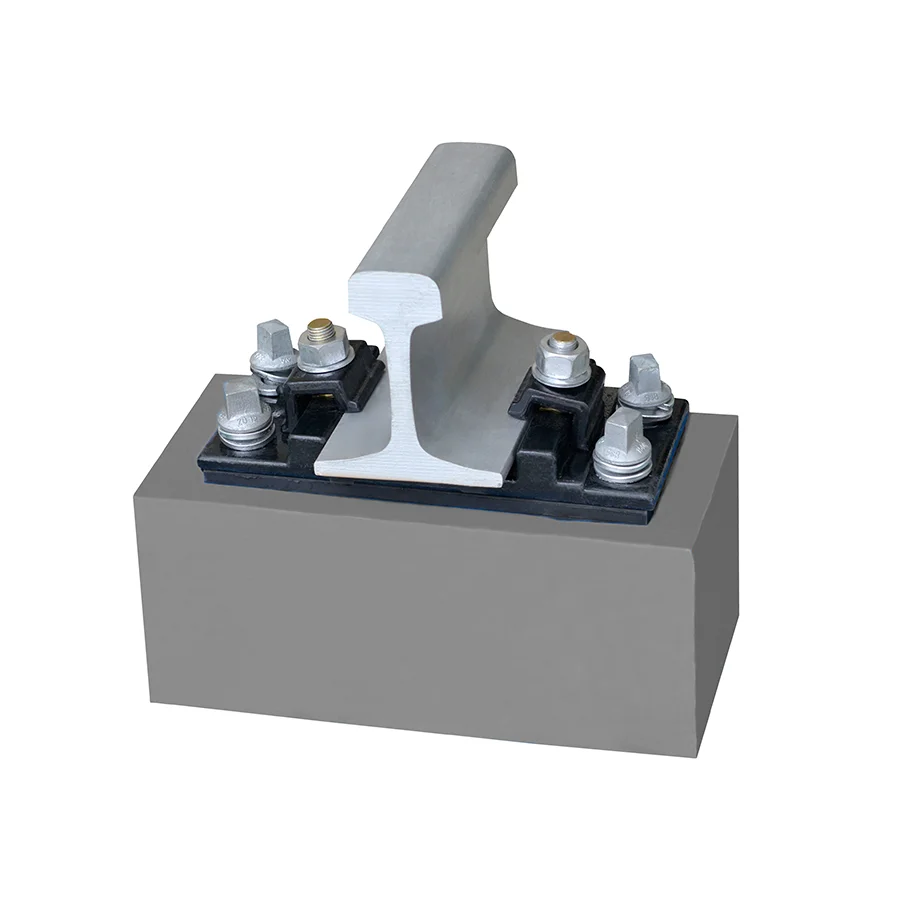

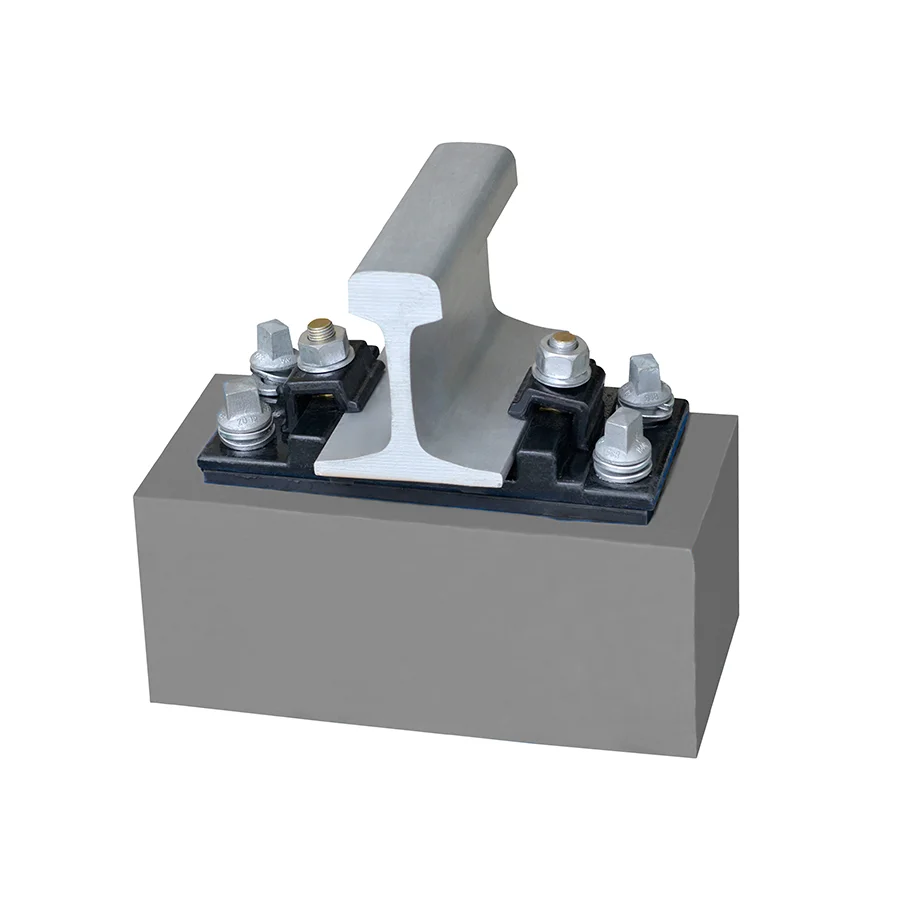

Key Components of Sleeper Fastener Systems

While designs vary among rail profiles and sleeper types, a complete sleeper fastener assembly typically includes:

-

Rail Clips or Clamps — such as elastic clips (e.g., SKL, Pandrol), providing clamping force and elasticity

-

Insulators and Pads — electrically isolate rails and absorb vibration

-

Screw Spikes or Anchor Bolts — secure fasteners to the sleeper body

-

Baseplates — ensure stable load transfer and long-term geometric accuracy

-

Shoulders / Sleeves — cast or embedded components for connecting clips and bolts

The performance of each component affects not only the lifespan of the track but also the safety and comfort of train operation.

Performance Characteristics That Define High-Quality Sleeper Fasteners

A professionally engineered sleeper fastener must withstand extreme operational environments. The most important characteristics include:

1. Long-Term Clamping Force Stability

A sleeper fastener must maintain its clamping force under millions of load cycles. Loss of clamping force can lead to rail misalignment, higher vibration, and premature track degradation.

2. Superior Elasticity and Fatigue Resistance

Elastic elements such as rail clips must endure high-frequency dynamic loads without deformation. Premium materials—spring steel, micro-alloyed steels, heat-treated composites—ensure these components retain elasticity over decades.

3. Corrosion and Weather Resistance

Tracks face moisture, salt, UV exposure, and temperature extremes. The best fasteners use advanced anti-corrosion coatings, hot-dip galvanizing, or alloy-enhanced materials to ensure longevity.

4. Electrical Insulation

For track circuits and modern signaling systems, electrical insulation is essential. Insulators and pads must maintain resistance under vibration, compression, and environmental stress.

Different Types of Sleeper Fasteners and Their Applications

Sleeper fasteners differ based on the rail system, load conditions, and sleeper type. Common categories include:

● Elastic Fastening Systems

Used widely in high-speed and heavy-haul networks (e.g., Pandrol, W-type systems). They deliver high elasticity, strong clamping force, and long fatigue life.

● Rigid Fastening Systems

Used in light-rail or special track sections requiring reduced elasticity. They offer robust positioning and long-term dimensional stability.

● Insulated Fasteners

Designed for lines with electrified signaling. They ensure high electrical resistance and stable insulation performance.

● Heavy-Haul Fasteners

Reinforced to support axle loads exceeding 30 tons, offering exceptional fatigue life and anti-creep stability.

Sleeper Fasteners vs. Other Rail Fastening Systems

While the term rail fastening system is broad, sleeper fasteners are specifically engineered for integration with sleepers, distinguishing them from fasteners used in:

Ballastless / slab tracks

Turnouts and special trackwork

Bridge expansion fasteners

Vibration reduction fasteners for metro systems

Compared with fasteners for slab tracks, sleeper fasteners offer:

Higher elasticity, reducing ballast abrasion

Simpler installation

Lower procurement and maintenance costs

Flexibility across multiple rail profiles and sleepers

These advantages explain why sleeper fasteners remain the backbone of global railway networks, particularly in mixed passenger-freight environments.

Why More Global Clients Choose HuiBo Railway Sleeper Fasteners

As a professional manufacturer of railway components, HuiBo Railway has earned long-term trust across Asia, Europe, the Middle East, and Africa. Our sleeper fasteners are widely used in both standard-gauge and heavy-haul lines, thanks to:

1. Full Control Over Materials and Manufacturing

We manufacture elastic clips, bolts, insulating components, and baseplates using controlled steel formulations and advanced heat-treatment technologies to ensure fatigue resistance and dimensional accuracy.

2. Engineering Support for Custom Projects

We provide technical consultation, drawing verification, and customization for:

High-speed rail

Metro and tram systems

Heavy-haul freight

Special track structures

3. Competitive Pricing Without Compromising Quality

By optimizing process technology and raw material supply chains, we help clients reduce total lifecycle costs while maintaining world-class performance.

Conclusion

The sleeper fastener is a small component in appearance, but it plays an indispensable role in track stability, operational safety, and maintenance efficiency. As railway systems expand globally, operators require solutions that combine durability, elasticity, electrical insulation, and adherence to strict standards.

Backed by years of experience in railway component manufacturing, HuiBo Railway continues to deliver sleeper fasteners engineered for high performance, long service life, and reliable supply—helping railway partners worldwide build safer and more efficient rail networks.