Role of Signal Stability in Modern Electronics

As electronic systems become more compact and functionally complex, maintaining stable signal transmission between wires and printed circuit boards is increasingly important. In many applications, the WTB Wire to Board Connector serves as a critical interface that directly affects data integrity, power delivery, and overall system reliability. Signal instability at this junction can result in noise, intermittent connections, or even complete system failure, making careful connector design and selection essential from the early stages of product development.

Contact Design and Electrical Continuity

A key factor in signal stability is the quality of the electrical contact between the wire terminal and the PCB contact point. Well-designed connectors use precisely shaped contacts that provide consistent normal force, ensuring low and stable contact resistance over time. This mechanical consistency helps prevent micro-gaps or oxidation-related resistance changes that could introduce signal loss or distortion. In a WTB Wire to Board Connector, maintaining uniform contact pressure across all terminals is especially important when multiple signals are transmitted simultaneously.

Material Selection and Plating Technology

The materials used for contacts and housings play a significant role in reducing signal degradation. High-conductivity copper alloys are commonly chosen to minimize resistive losses, while surface plating, such as tin or gold, improves corrosion resistance and electrical reliability. Insulating materials with stable dielectric properties help reduce signal leakage and electromagnetic interference. By carefully matching conductive and insulating materials, manufacturers enhance the connector’s ability to support stable signal transmission under varying electrical and environmental conditions.

Mechanical Stability and Vibration Resistance

Mechanical movement is a hidden but critical source of signal instability. Vibration, shock, or thermal expansion can cause slight shifts in contact position, leading to momentary signal interruption or noise. Connectors designed with secure locking mechanisms and robust housings help maintain alignment between the wire and the board. This mechanical stability ensures that electrical paths remain intact even in demanding environments such as automotive electronics or industrial equipment.

Layout Compatibility and Signal Integrity

Signal stability is influenced not only by the connector itself but also by how it integrates into the PCB layout. Proper pin arrangement, adequate spacing, and well-defined signal return paths help minimize crosstalk and electromagnetic interference. When connector geometry aligns with optimized PCB routing, impedance discontinuities are reduced, allowing signals to pass through the interface with minimal reflection or attenuation. This holistic approach strengthens the overall performance of the interconnection system.

Long-Term Reliability and Application Demands

Over the lifetime of a product, connectors are exposed to temperature changes, humidity, and repeated electrical loading. A well-engineered WTB Wire to Board Connector is designed to maintain its electrical and mechanical characteristics under these conditions. By combining precise contact design, suitable materials, mechanical robustness, and layout compatibility, such connectors provide consistent signal stability. This reliability is essential for supporting long-term operation in both consumer and industrial electronic applications.

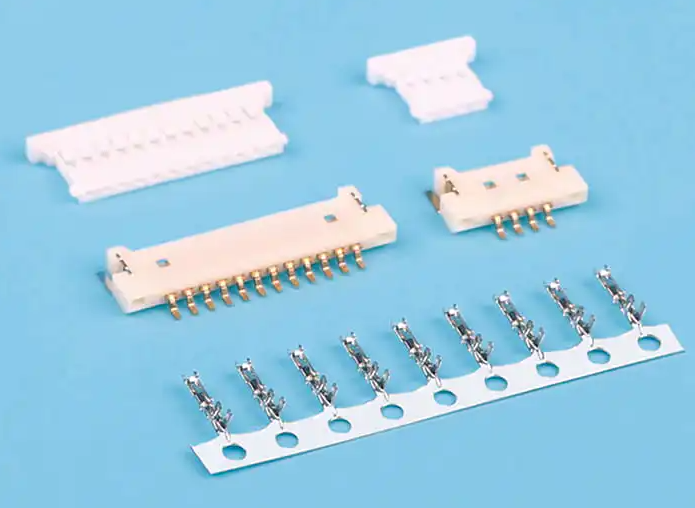

1、CKT: 2Pin to 25Pin

2、Current rating: 0.5A AC/DC

3、Voltage rating(max): 30V, AC/DC

4、Working Temperature: -25°C~+85C,

(Including temperature rise in applying electrical current)

5、Contact resistance: Initial value s20mΩ

After environmental testing≤40mΩ

6、Insulation resistance: 2100MΩ

7、Withstand voltage: 200VAC(rms)

8、Applicable wire: AWG #32 to #28

9、Applicable PCB board thickness: 1.6mm to 2.0mm