United States of America– 29 Dec 2025- The encapsulated gaskets and seals market continues to surge forward, propelled by stringent environmental regulations and the need for reliable sealing in harsh conditions. These components, featuring a soft core encased in durable materials like PTFE or metal, excel in preventing leaks across diverse sectors.

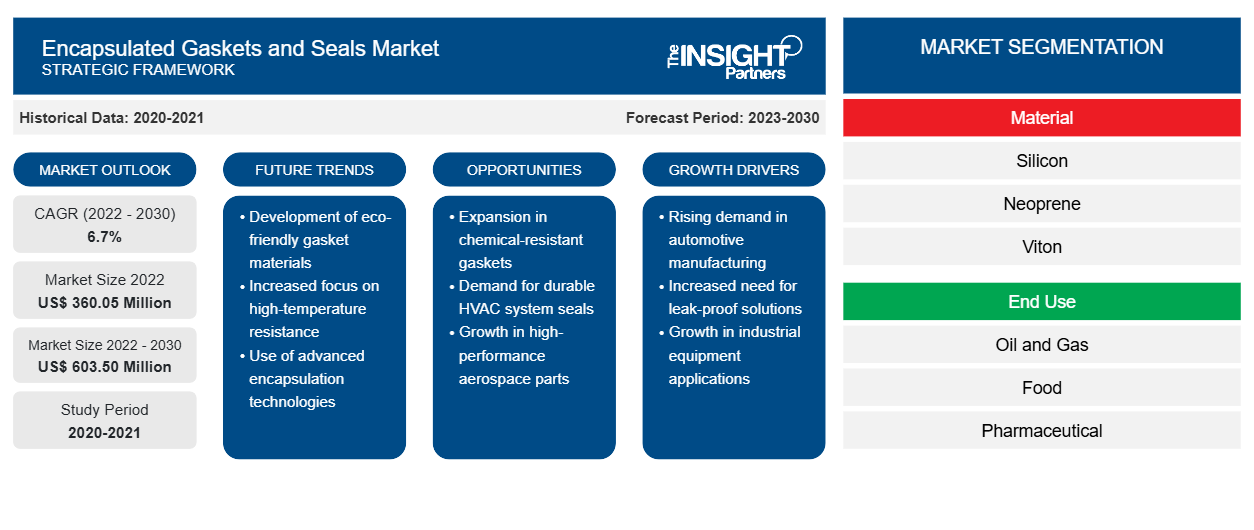

The encapsulated gaskets and seals market size was valued at US$ 360.05 million in 2022 and is expected to reach US$ 603.50 million by 2030; it is estimated to register a CAGR of 6.7% from 2022 to 2030.

Market Overview

Encapsulated gaskets and seals combine a compressible elastomer core with a protective outer layer, delivering superior chemical resistance, temperature tolerance, and longevity. Industries favor them for sealing flanges, valves, and pipelines where traditional options falter under extreme pressures or corrosives. Their versatility supports applications from oil exploration to pharmaceutical processing, ensuring system integrity and operational efficiency.

Key Growth Drivers

Stringent safety standards worldwide push demand, as these seals minimize leak risks and environmental harm. Rising awareness of leak prevention aligns with regulatory pressures, compelling industries to adopt advanced sealing solutions. Material science innovations, including high-performance polymers and elastomers, enhance durability and broaden usability in demanding environments.

Expanding industrialization, particularly in oil and gas, amplifies needs for robust seals in wellheads, pipelines, and storage vessels. Automotive and aerospace sectors leverage their reliability for high-stakes assemblies, while chemical processing relies on them to contain hazardous substances.

Major Challenges

Competition from traditional gaskets, O-rings, and simpler seals poses hurdles, as cost-sensitive users opt for alternatives in less extreme settings. These substitutes offer easier installation and lower upfront costs, potentially slowing adoption where encapsulation seems excessive. Supply chain disruptions, echoed from past pandemics, highlight vulnerabilities in manufacturing and delivery, urging diversified sourcing.

Download PDF Copy- https://www.theinsightpartners.com/sample/TIPRE00027544

Segment Insights

By material, options like silicone, neoprene, Viton, and Teflon cater to specific needs—Viton leads for heat and fluid resistance, while Teflon shines in corrosive chemical environments. End-use spans oil and gas for infrastructure sealing, chemicals for process safety, pharmaceuticals for hygiene, food for compliance, automotive for engines, and others like aerospace.

Chemical applications dominate due to high-pressure processes demanding leak-proof barriers against corrosives. Oil and gas remains pivotal, with seals ensuring no fluid or gas escapes in extreme conditions.

Regional Dynamics

Asia Pacific spearheads growth through rapid industrialization in oil and gas, automotive, and pharmaceuticals, where reliable seals optimize efficiency. Europe advances via technological progress and strict regulations across automotive, chemical, and energy sectors. North America benefits from ongoing energy extraction, both onshore and offshore, requiring resilient components.

Competitive Landscape

Leading players include Trelleborg AB, Marco Rubber & Plastics LLC, Gasco Inc, VH Polymers, AS Aston Seals SPA, Seal & Design Inc, MCM SPA, Polymax Ltd, Vulcan Engineering Ltd, and ROW Inc. These firms prioritize quality and innovation to meet diverse demands.

Strategic moves define the arena: Trelleborg acquired a South Korean precision seals maker in late 2023 for semiconductor expansion, while Seal & Design integrated Chamberlin Rubber Company early that year. Recent activities, like Carco PRP Group's purchase of ROW Inc and Integrated Polymer Solutions' acquisition of Oldham Seals, signal consolidation for enhanced portfolios.

Future Outlook

Technological strides promise smarter, customized seals with improved formulations for sustainability. As industries prioritize safety and efficiency, encapsulated solutions will expand into emerging areas like renewables and advanced manufacturing. Stakeholders must navigate alternatives and supply risks to capitalize on this trajectory.

Related Reports-

High Temperature Gasket Materials Market

High Temperature Gaskets Market

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients get solutions to their research requirements through our syndicated and consulting research services. We specialize in semiconductor and electronics, aerospace and defense, automotive and transportation, biotechnology, healthcare IT, manufacturing and construction, medical devices, technology, media and telecommunications, and chemicals and materials.

Contact Us:

If you have any queries about this report or if you would like further information, please get in touch with us:

Contact Person: Ankit Mathur

E-mail: ankit.mathur@theinsightpartners.com

Phone: +1-646-491-9876

Also Available in : Korean| German| Japanese| French| Chinese| Italian| Spanish