Introduction to Slip Resistance

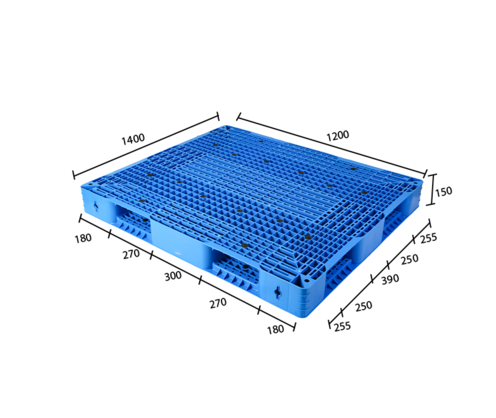

The stability of stacked pallets in warehouses and transportation systems depends heavily on their slip resistance. A Double-Faced Grid Plastic Pallet features a textured or ribbed surface on both sides, designed to minimize sliding between the pallet layers. Unlike smooth-surfaced pallets, the enhanced grip of a double-faced grid design prevents lateral movement, reducing the risk of toppling when pallets are stacked high. This property is particularly important in dynamic environments where forklifts and pallet jacks are constantly moving loads.

Impact on Stacking Safety

Stacking pallets safely is a critical concern for warehouse efficiency and worker safety. A Double-Faced Grid Plastic Pallet with high slip resistance ensures that each pallet maintains its position relative to the others. When pallets are loaded with uniform or irregular weights, the textured surface distributes pressure more evenly and reduces the chance of shifts during stacking. This minimizes accidents, product damage, and operational delays caused by pallet instability.

Load Distribution and Stability

The anti-slip design of a Double-Faced Grid Plastic Pallet also influences load distribution. By preventing minor shifts between stacked layers, the pallet maintains structural integrity under heavier loads. Proper load distribution reduces stress on individual pallets, preventing warping or cracking that can occur with repeated stacking. As a result, the slip-resistant surface directly contributes to the long-term durability of both the pallets and the products being stored.

Operational Efficiency

High slip resistance on double-faced grid pallets improves operational efficiency in logistics and storage. Workers can stack pallets higher with confidence, knowing that the risk of slippage is minimized. This allows warehouses to maximize vertical storage space without compromising safety. Additionally, secure stacking reduces the need for extra securing measures, such as straps or shrink wrap, saving both time and cost in routine warehouse operations.

Environmental Considerations

Double-Faced Grid Plastic Pallets are often used in environments that require resistance to moisture, chemicals, and temperature variations. Their slip-resistant surfaces maintain performance even in wet or slightly oily conditions, where traditional smooth pallets might fail. This feature is particularly valuable in food, pharmaceutical, and chemical industries, where both product protection and stability are essential.

Conclusion

In conclusion, the slip resistance of a Double-Faced Grid Plastic Pallet plays a vital role in maintaining stack stability. By preventing lateral movement, enhancing load distribution, and improving operational efficiency, these pallets ensure safer, more reliable, and space-efficient storage solutions. For businesses looking to optimize warehouse safety and durability, selecting a double-faced grid design with superior anti-slip performance is a critical decision.